From the city to the sea, there are many environments and creatures that we need to protect together, and with the rapid changes in technology, it is easy to overlook the ecology around us.Through the illustration, we are reminded that the marine ecology and the protection of the earth's environment are both interdependent and mutually beneficial, and that we can always feel the continuous ecological chain!

Our goals and commitments

Amidst the impact of global climate change, Quanta is committed to pursuing sustainable development for the planet. We strive to reduce carbon emissions and manage energy use effectively, while also designing products with energy efficiency in mind. We focus on reducing the use of packaging materials and minimizing production waste. Through the participation and commitment of all employees, we aim to achieve environmental protection and corporate sustainability. Quanta has pledged, under the agreement of the board of directors, to reduce carbon emissions by 4.2% annually until 2032, with a 42% reduction in Scope 1 and Scope 2 emissions and a 25% reduction in Scope 3 emissions compared to 2022. By 2030, 50% of the Group's energy consumption will come from renewable sources, and by 2050, we will achieve carbon neutrality.

Our concrete achievements include

- High-level support is obtained through the participation of executives at the vice president level and above in discussions to build consensus.

- In March 2022, Quanta established a Climate Change Committee to promote cross-plant and cross-department communication and coordination, making energy conservation and carbon reduction a collective action throughout the entire group.

- A commitment letter was submitted to the SBT initiative, pledging to contribute to limiting global warming to no more than 1.5 °C.

- A Sustainable Development Center was established to manage group-wide sustainability affairs. The head of the Sustainable Development Center regularly reports on progress in greenhouse gas inventories and policies to address climate change at board meetings, receiving support from the Board of Directors.

- The Task Force on Climate-related Financial Disclosures (TCFD) was implemented to identify climate change risks and opportunities.

- The construction of a carbon management platform was initiated, starting with the completion of an internal carbon inventory system based on ISO 14064-1:2018, laying the foundation for further measures such as energy management, product life cycle management, and internal carbon pricing.

- Green energy was purchased to account for 25.92% of the total electricity consumption of four plant sites.

- Compared to 2021, the results of ISO 14064-1 carbon inventory have decreased by 362,854 metric tons, achieving a reduction of 53.35% in carbon emissions. The million-dollar revenue emission intensity has decreased from 0.602 to 0.248.

- Zero-waste landfill projects have been gradually promoted at all plant sites. QTMC, QC1, QCMC, and QMB obtained platinum and silver level certifications in 2022.

- A full materials declaration (FMD) management system was introduced to identify potential hazardous substances in product components and reduce the risks to human health and the environment.

- Quanta designed products that are easy to disassemble and recycle, in compliance with the Waste Electrical and Electronic Equipment Directive (WEEE). Products developed in 2022 were certified in accordance with WEEE regulations, and the WEEE recycling logo was marked on the products. The estimated percentage of recyclable materials used was above 80%.

-

The company obtained 78 EPEAT ecolabels, 42 TCO verifications, and 76 Energy Star

certifications.

In 2022, Quanta did not have any major violations of environmental regulations, and all shipped products were 100% compliant with customer and regulatory requirements, with no violations related to customer health and safety.

Identification of TCFD Climate Risks and Opportunities

In order to achieve the target, Quanta established a Climate Change Committee in March 2022 to coordinate cross-plant and cross-departmental horizontal communication so that energy saving and carbon reduction will become a common action for the whole group, The four main axes of governance, strategy, risk management, indicators, and targets in the TCFD framework are used for risk governance and identification, strategy management, and contextual and cost analysis to summarize, model, and quantify the financial impacts of climate risks in different scenarios, in order to refine the sustainable development goals of energy conservation and carbon reduction:

The board of directors and management oversee climate-related risks and

opportunities.

▶Sustainability Steering Committee

Quanta has established a " Sustainability Steering Committee ", which, according to its work plan, convenes committee meetings at least twice a year to discuss annual plans and progress toward goals, review the work items of each committee meeting, and discuss future development strategies, concrete achievements, and work directions. The committee provides regular reports to the board of directors each quarter. At the end of each fiscal year, it compiles stakeholder identification and communication information in the most recent board report for the following year. The board directly guides the company's sustainable development strategy and makes ESG an important governance policy through regular reporting driven by sustainability-related affairs.

The role of management in assessing and managing climate-related risks and

opportunities.

▶Sustainability Development Center

To effectively promote sustainability work and enhance ESG performance, the previously cross-departmental project task forces have been elevated to a dedicated department known as the "Sustainability Development Center". This center reports directly to the General Manager's Office and actively plans and implements digital sustainable management systems. It collects and consolidates sustainability-related data from various plant sites and business units to ensure data logic is relevant and consistent. It systematizes the scrutiny of greenhouse gas emissions and product carbon footprints, establishes a document management system, improves the efficiency of reviewing decarbonization data, and formulates precise decarbonization strategies.

▶Climate-related Sustainability Governance Committee

Subcommittees under the Sustainability Development Guidance Committee are composed of senior executives from relevant units as management representatives. The business contents are explained as follows:

| Committee | Content |

|---|---|

| Climate Change Management Committee | Responsible for matters such as greenhouse gas inventory, green procurement, and supply chain management within the organization. It formulates decarbonization actions, sets relevant implementation plans according to annual targets, and regularly tracks and reviews progress. |

| Environmental Protection Committee | Integrates environmental health and safety management within the organization, continuously promotes the operation of ISO14001, ISO45001, ISO14064, ISO50001 management systems, and formulates and monitors relevant environmental health and safety performance indicators. |

| Green Product Committee | Manages green product design and production, keeps up with the latest international electronic product chemical substance specifications, and incorporates them into green product management policies and guidelines to ensure that 100% of shipped products comply with customer and regulatory requirements, implementing the spirit of ESG. |

| ■ For more detailed information and organizational hierarchy, please refer to the Sustainability Development Organizations section. | |

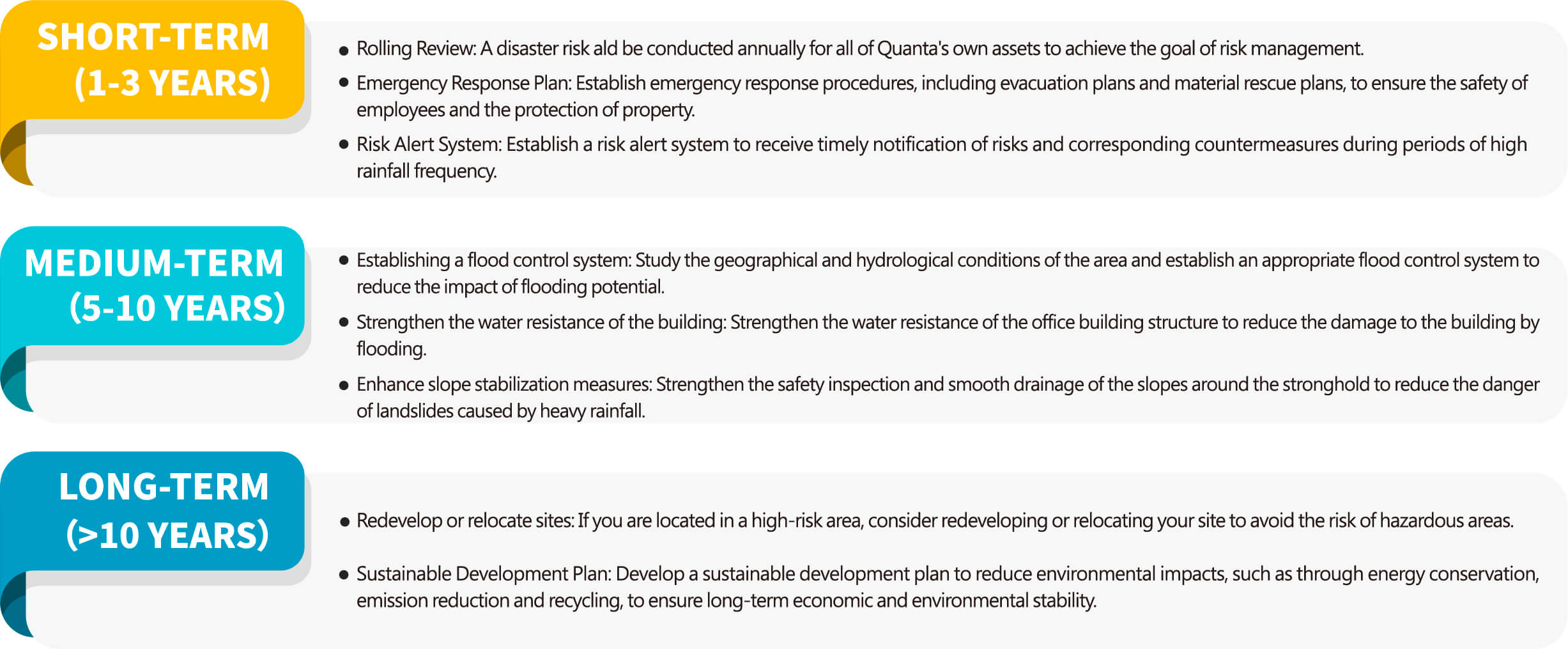

Organizational Identification of Short, Medium, and Long-Term Climate-Related Risks and Opportunities

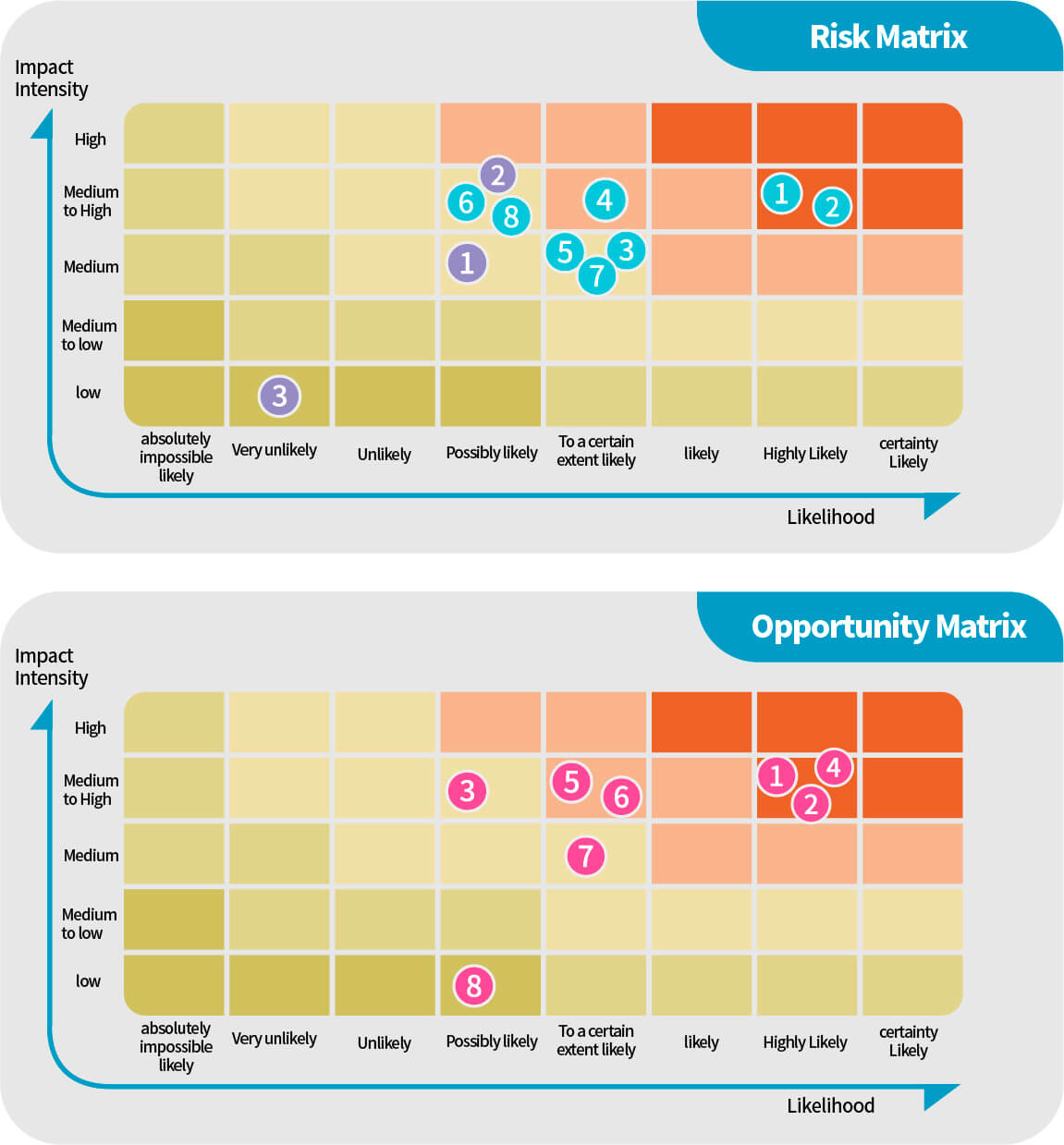

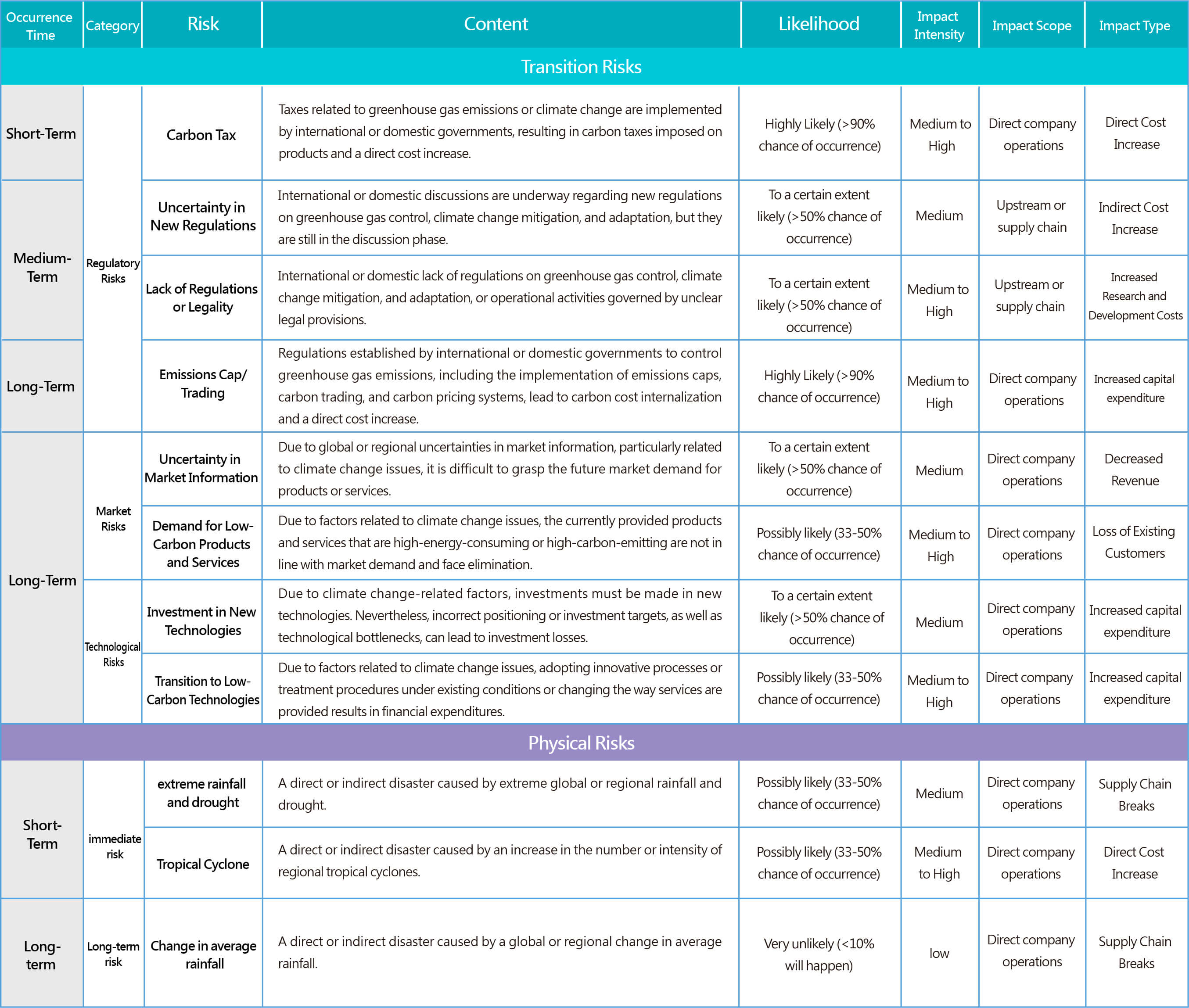

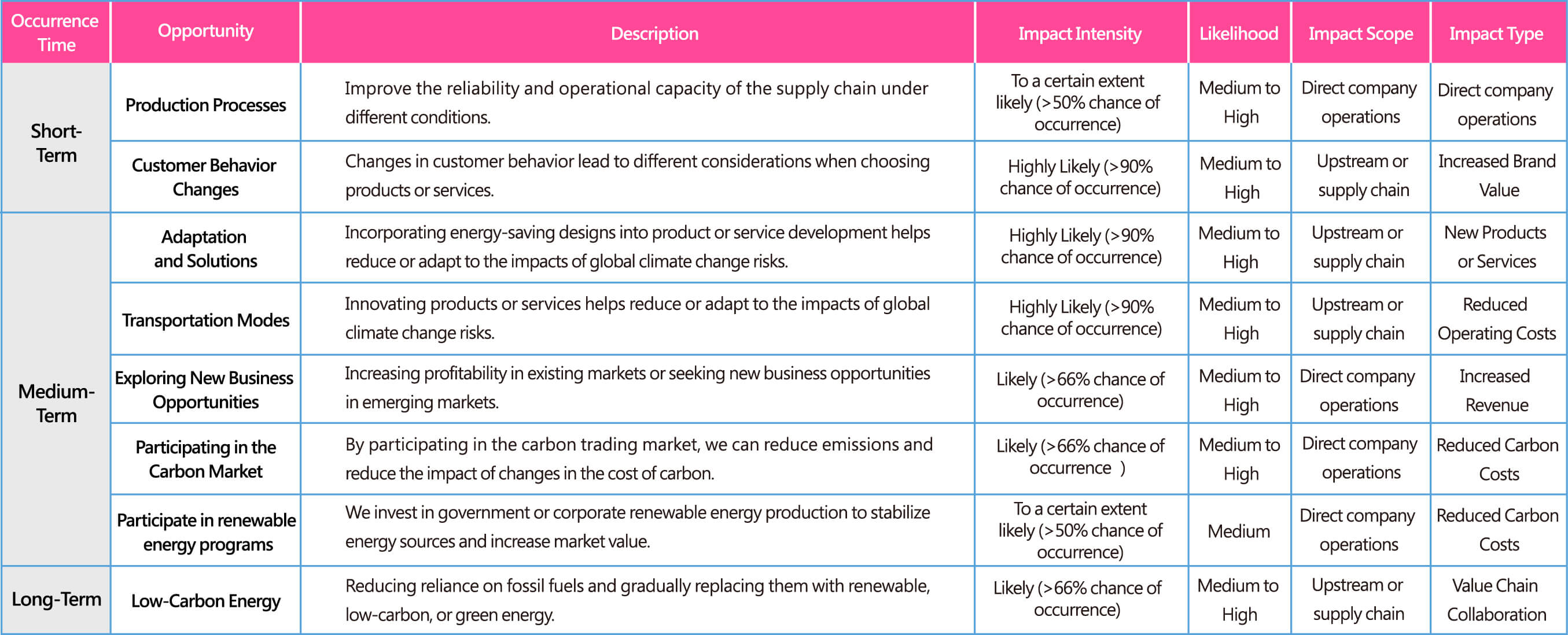

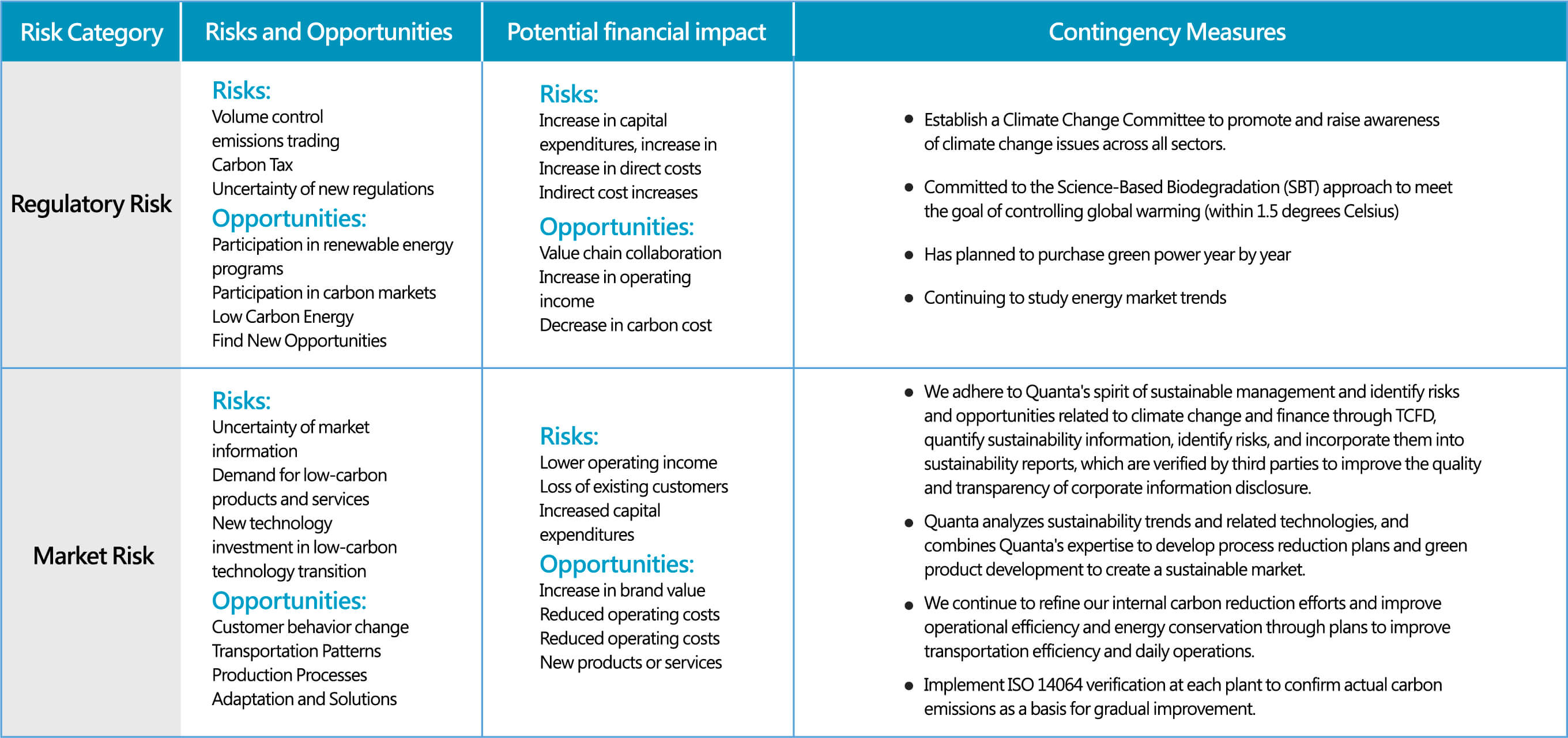

Quanta's internal digital TCFD management system collects the impact analysis of each business unit on climate related risks and opportunities, and summarizes them in terms of time of occurrence, impact intensity, likelihood, impact range, etc., and scope are considered to identify short-term (1-3 years), medium-term (3-5 years), and long-term (5 years and beyond) climate-related risks and opportunities faced by Quanta. For Quanta, The physical risk is immediate (extreme rainfall and drought, tropical cyclones as risk) and long-term (change in average rainfall),transition risks originate from regulatory risks (carbon taxes, emissions trading systems, uncertainties in new regulations) and technological risks (demand for low-carbon products and services, investments in new technologies, low-carbon technology transformation). Transition opportunities arise from changes in customer behavior, transportation modes, adaptation solutions, low-carbon energy, and the search for new business opportunities. Detailed explanations are as follows:

Risk Matrix (constructed based on risk descriptions)

Opportunity Matrix

Climate related risk and opportunity shocks

Results of climate related risk and opportunity scenario analysis

Transformation Risk Scenario Analysis Results

With the development of international regulations and trends, Quanta is committed to follow the SBTi emission reduction target and strive to reduce carbon emissions. Quanta conducted a difference analysis between BAU and different external scenarios (government net zero path, SSP1-1.9, SBT-NZ) for future estimated emissions to project and quantify the climate related risks and opportunities, the results are as follows:

| Scenario | Assumed Parameters | Scenario Analysis Results |

|---|---|---|

| Government Net-Zero Pathway | Carbon tax of 300 NTD/tCO2e (approximately 10 USD/tCO2e) | Due to the uncertainty of market information and the demand for low-carbon products and services driven by international trends and market growth, the market risk of potential business losses is expected to increase, In addition, there will be a financial impact of paying carbon tax/fees and purchasing renewable energy due to regulatory requirements. |

| SSP1-1.9 | Carbon price for SSP1-1.9 | The market risk of potential business losses is expected to be consistent with the government's net-zero pathway. The main risk arises from the increasing carbon taxes, or carbon fees, projected based on the growing trend of carbon price per ton under the SSP1-1.9 scenario. Quanta may face higher expenses in carbon taxes or carbon fees in the future. |

| SBT-NZ Target |

Physical risk scenario analysis results

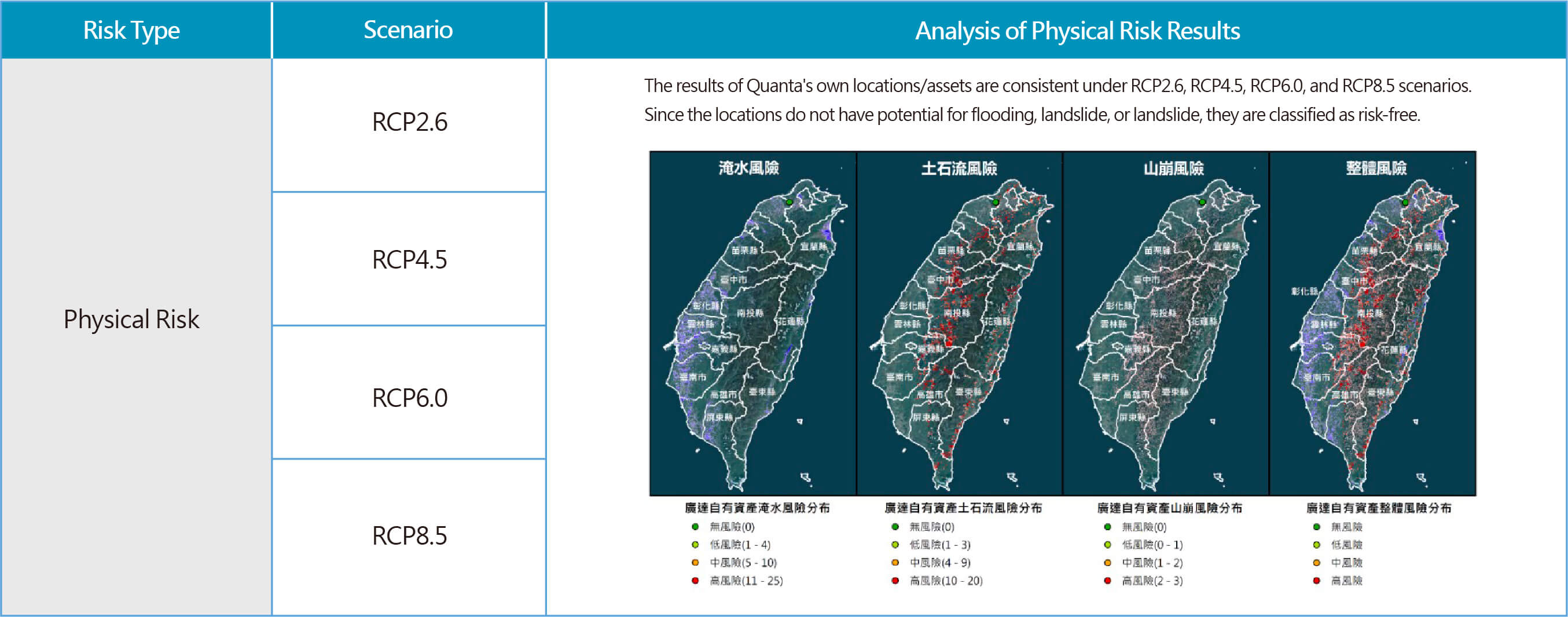

Climate risk is composed of hazard, exposure, and vulnerability. Quanta analyzed the risk values of each site using extreme rainfall as the hazard, extreme rainfall-induced flooding, landslides, and landslides as the vulnerability, and the location of the site as the exposure. The hazard level was evaluated by using multiple climate models (GCM/ESM) to simulate the climate risk of RCP2.6, RCP4.5, RCP6.0, and RCP8.5 scenarios to avoid extreme simulation results. Finally, the risk scores of the three vulnerability levels of flooding, landslide, and debris flow were classified into three risk levels of no risk, low risk, medium risk, and high risk according to the risk classification matrix, and the total risk was represented by the level with the highest risk value for the three vulnerability levels. The following is a description of Quanta's risk levels in each RCP scenario:

Analysis of Physical Risk Results

Quanta Entity Risk Adjustment Program:

Even in a risk-free situation, Quanta still has contingency plans and risk management measures in place, including establishing emergency response procedures, such as preparing evacuation plans and rescue supplies, to ensure the safety of employees and protection of property, and considering further enhancing the water resistance of its building structures and risk management systems to reduce the risk and loss that may occur in the future.

Quanta is committed to constructing and maintaining a complete climate related risk management system, and includes the entire group organization and subsidiaries in its risk management scope. The risk management policy defines the various types of climate-related risks in accordance with the Company's operational policy, and prevents possible losses and optimizes resource allocation in order to reasonably ensure the achievement of the Company's strategic objectives

▶Identification and Evaluation Process of Climate Related Risks

Quanta follows the TCFD risk disclosure recommendations and collects and summarizes the results of climate related risk and opportunity analysis by each business unit through a digital management system, based on factors such as time of occurrence, impact intensity, likelihood, and impact range, to identify the impact of climate related risks and opportunities, and use them as a basis for formulating response strategies.

▶Climate related risk management process

Quanta has established the "Sustainable Development Steering Committee" and its working group conducts short-, medium- and long-term impact assessments and management of climate-related risks every year, and proposes improvement plans for high-risk items. The assessment results and improvement plans are approved by the management representatives of each plant, endorsed by the president, and submitted to the board of directors for approval before being taken forward and implemented. Quanta's board of directors directly directs the company's strategy for sustainable development, and the "Sustainable Development Center", a special department, is directly responsible to the president's office for making ESG an important guideline for corporate governance.

▶Overall Organizational Process for Identifying and Assessing Climate Risks

Quanta has established the "Risk Management System", which is approved by the Board of Directors, with the President as the convener, to coordinate the promotion and operation of the plan, with the participation and cooperation of all employees. The Sustainability Steering Committee coordinates the possible impact of climate-related risks on operations or profitability, and formulates strategies and proactively communicates with stakeholders of risk events in order to reduce the impact of risk events on the Company's operations and protect the interests of stakeholders.

Quanta has established its own "Risk Management System" and introduced the Climate Related Financial Disclosure (TCFD), and established a working group to identify and evaluate climate related risks in advance. The risk management process is based on five major themes: risk identification, risk measurement, risk monitoring, risk reporting and disclosure, and risk response from four major perspectives: governance, strategy, risk management, and objectives, and the identification of risks and relative opportunities are reported to the Board of Directors. The Company communicates with all stakeholders to disclose the results of risk identification and management, and discloses risk management information in the annual report, ESG report, and website, please refer to quantatw.com for details.

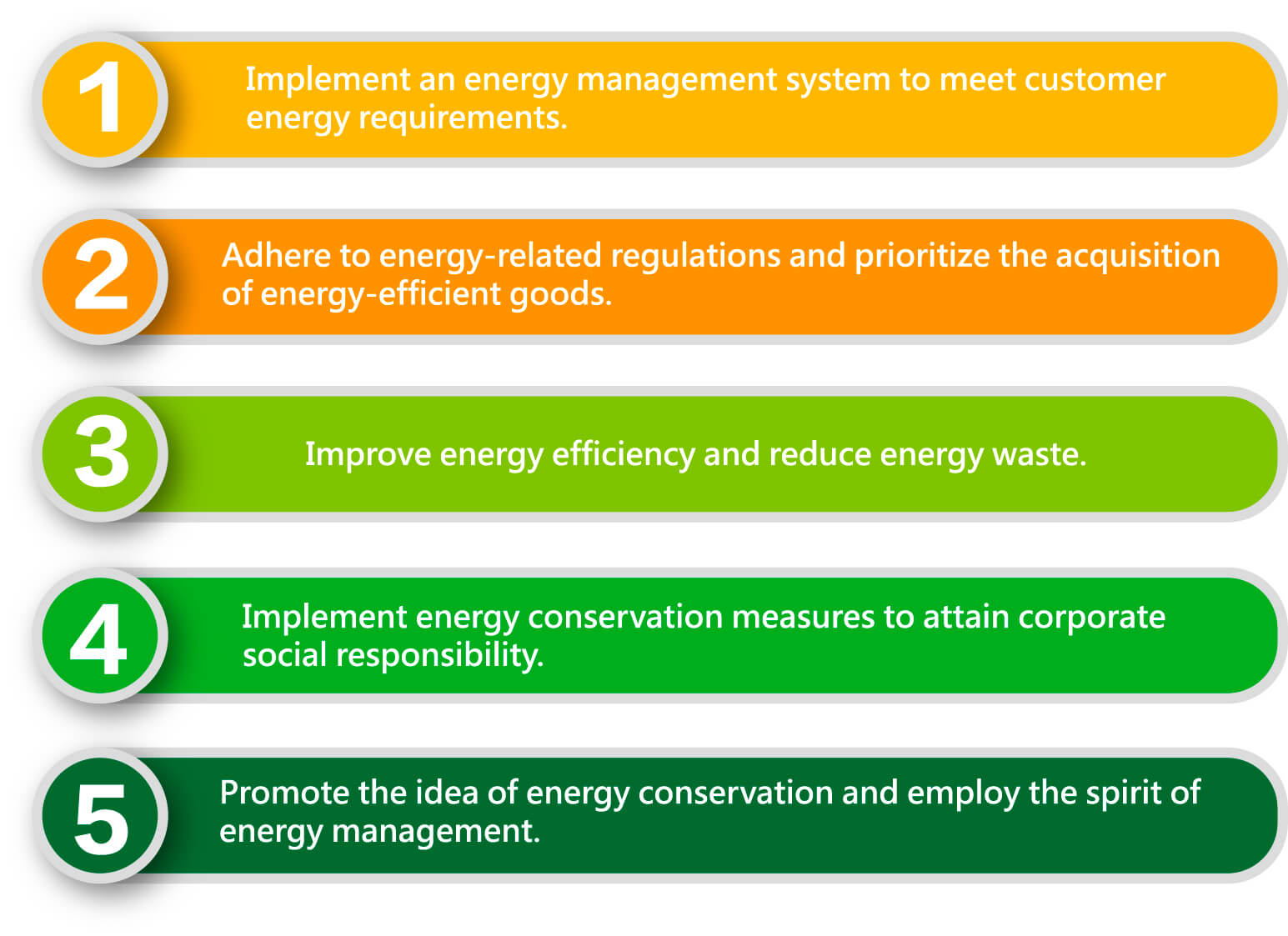

The company actively implements the ISO 50001:2018 Energy Management System and has established the following policies:

Quanta Computer is a professional design and manufacturing company of portable computers, laptops, motherboards, servers, and other electronic products. We uphold the belief in coexistence with the Earth and recognize the limited resources of our planet and the importance of sustainable development for our company. Therefore, based on our understanding of energy conservation and carbon reduction, the enhancement of energy efficiency, and fulfilling our corporate social responsibility, we commit to implementing the requirements of the ISO 50001 Energy Management System international standard. We strive to continuously improve energy efficiency, reduce energy consumption in our production or operational activities, establish appropriate energy management performance indicators, and fulfill the following commitments:

The Company commits to educating and informing all employees in order for them to comprehend and adhere to this policy, which may be made available to the public.

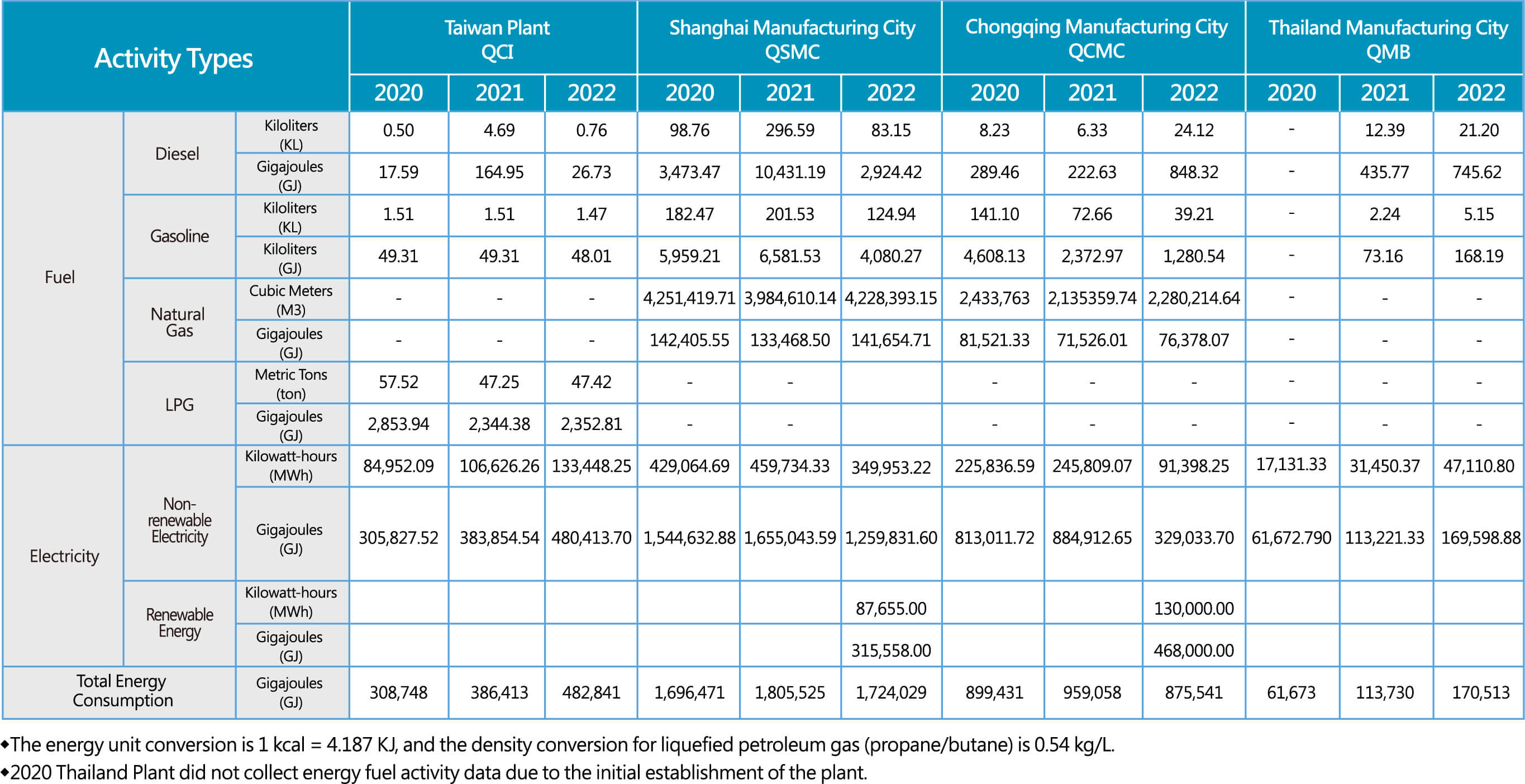

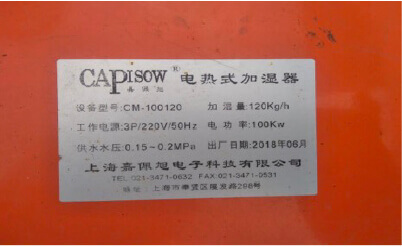

Currently, the company uses non-renewable energy sources, including gasoline and diesel for company vehicles, natural gas for boilers, liquefied petroleum gas for employee cafeterias, diesel for emergency generators, and purchased electricity. The data sources are based on the 2022 greenhouse gas inventory reports from each plant site, and the calorific value data is obtained from the Energy Bureau's 2015 Energy Product Unit Heat Value Table. The calculation formula is as follows: Energy Consumption = Energy Usage x Energy Heat Value x Energy Unit Conversion.

Types of Energy Consumption

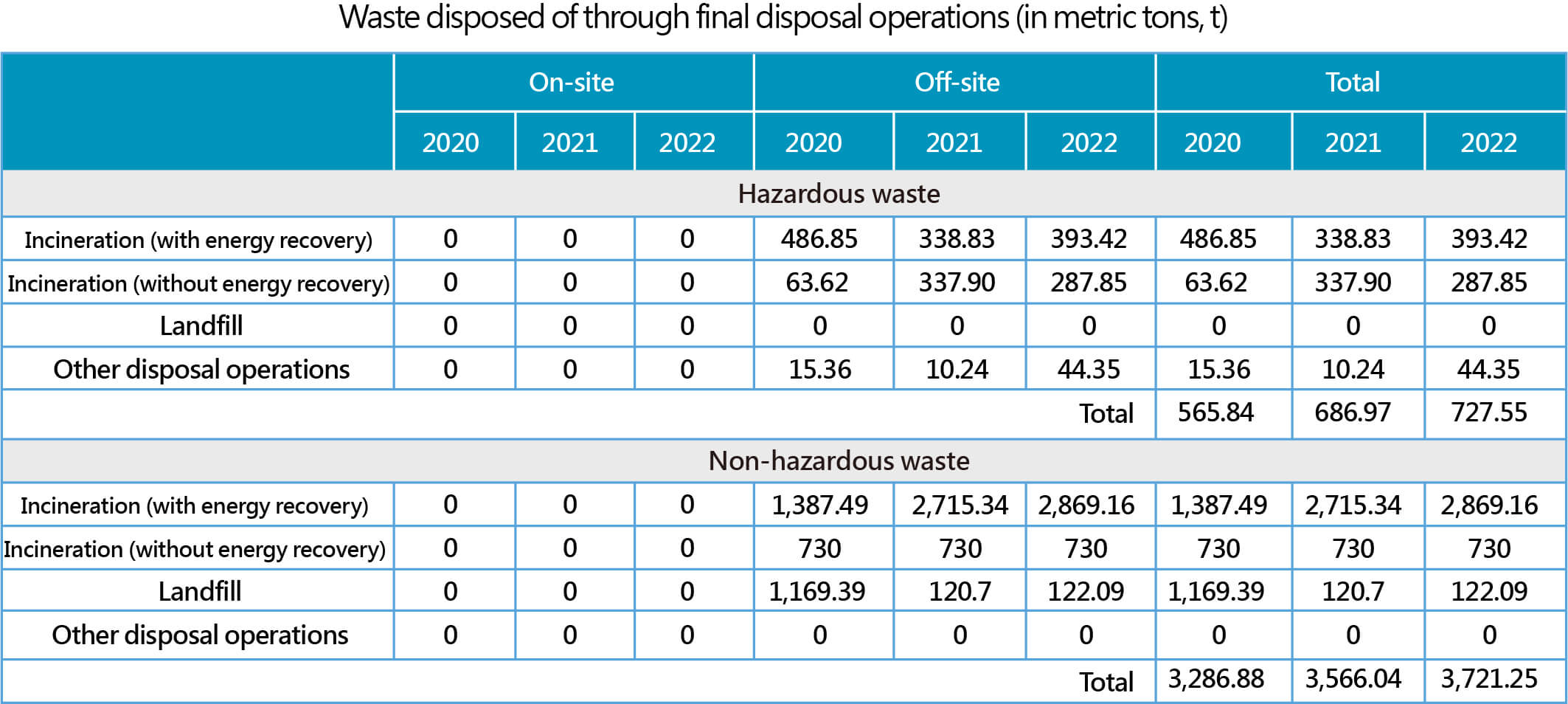

Reduction Performance

| Plant | Target | Effect |

|---|---|---|

| Taiwan plant | According to the regulations of the Ministry of Economic Affairs' "Energy Administration Act," the Taiwan plant sets energy-saving goals and implements plans, achieving an annual electricity saving rate of over 1%. | In the Taiwan plant, 10 measures were implemented, including replacing lighting equipment in office areas, increasing the load of the chilled water system on non-production days, and reducing the operating load of the production line's air conditioning units. These measures resulted in a total energy saving of 1,915,697.217 kWh |

| China plants | According to the regulations of the Ministry of Economic Affairs' "Energy Administration Act," the Taiwan plant sets energy-saving goals and implements plans, achieving an annual electricity saving rate of over 1%. | The Shanghai plant implemented 43 management schemes, including air conditioning frequency conversion retrofitting and equipment shutdown during holidays, resulting in a total energy savings of 20,856,433.8 kWh. The Chongqing plant achieved a total energy savings of 4,976,033.5 kWh through five measures, including the implementation of the QECS energy-saving program. |

Energy Performance Indicators

| Performance Indicators | Unit | 2022 |

|---|---|---|

| Electricity Consumption per Million Revenue | kWh/million revenue | 655.12 |

| Percentage of Renewable Energy | % | 25.92 |

| Note: The energy efficiency performance indicator intensity ratio covers the type of electricity. | ||

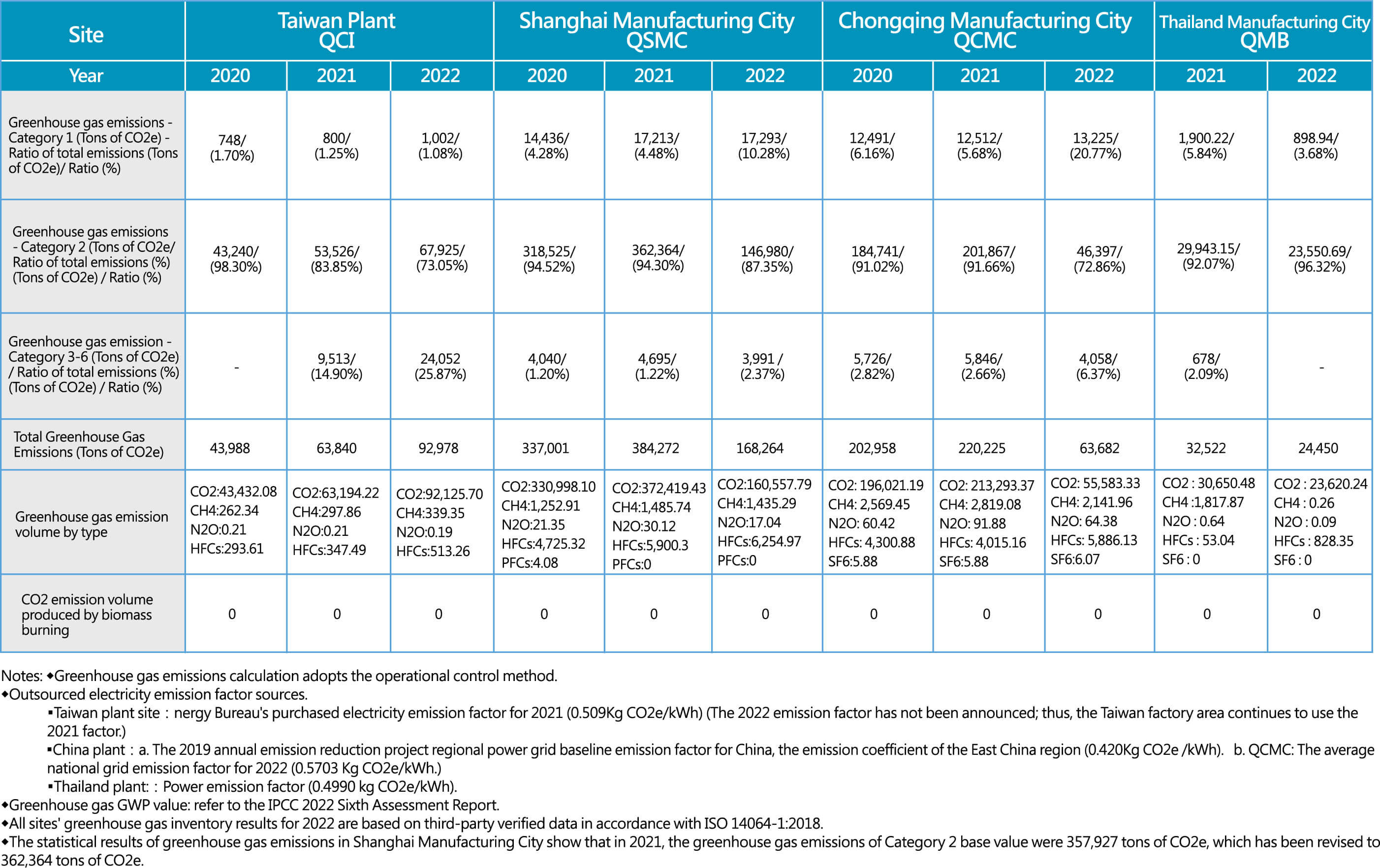

The types of greenhouse gases and the categories of inventory

Quanta's greenhouse gas types include CO2, CH4, N2O, HFCs, PFCs, SF6, and NF3. The main emission sources include natural gas, diesel, gasoline, liquefied petroleum gas, CO2 fire extinguishers, methane from septic tanks, refrigerant leakage, and purchased electricity. Based on historical statistics, the main source of Quanta's greenhouse gas emissions is purchased electricity for operational needs. Excluding other indirect emissions, this emission source accounts for over 90% of the company's total emissions in 2020.

In accordance with ISO 14064-1:2018 and the Greenhouse Gas Inventory Protocol requirements, Quanta has established a greenhouse gas emission inventory and conducts regular annual greenhouse gas emission inventories. Verification statements are obtained to serve as the basis for energy saving and carbon reduction. Quanta actively responds to government policy trends, annually formulates energy-saving and emission reduction measures and targets, and gradually establishes a comprehensive greenhouse gas emission statistical accounting system. The inventory scope includes qualitative and quantitative inventories of Category 1 (direct greenhouse gas emissions) and Category 2 (indirect greenhouse gas emissions from energy sources).

Quanta's original base year was 2021, but due to the introduction of SBTi in 2022, the base year has been changed to 2022.

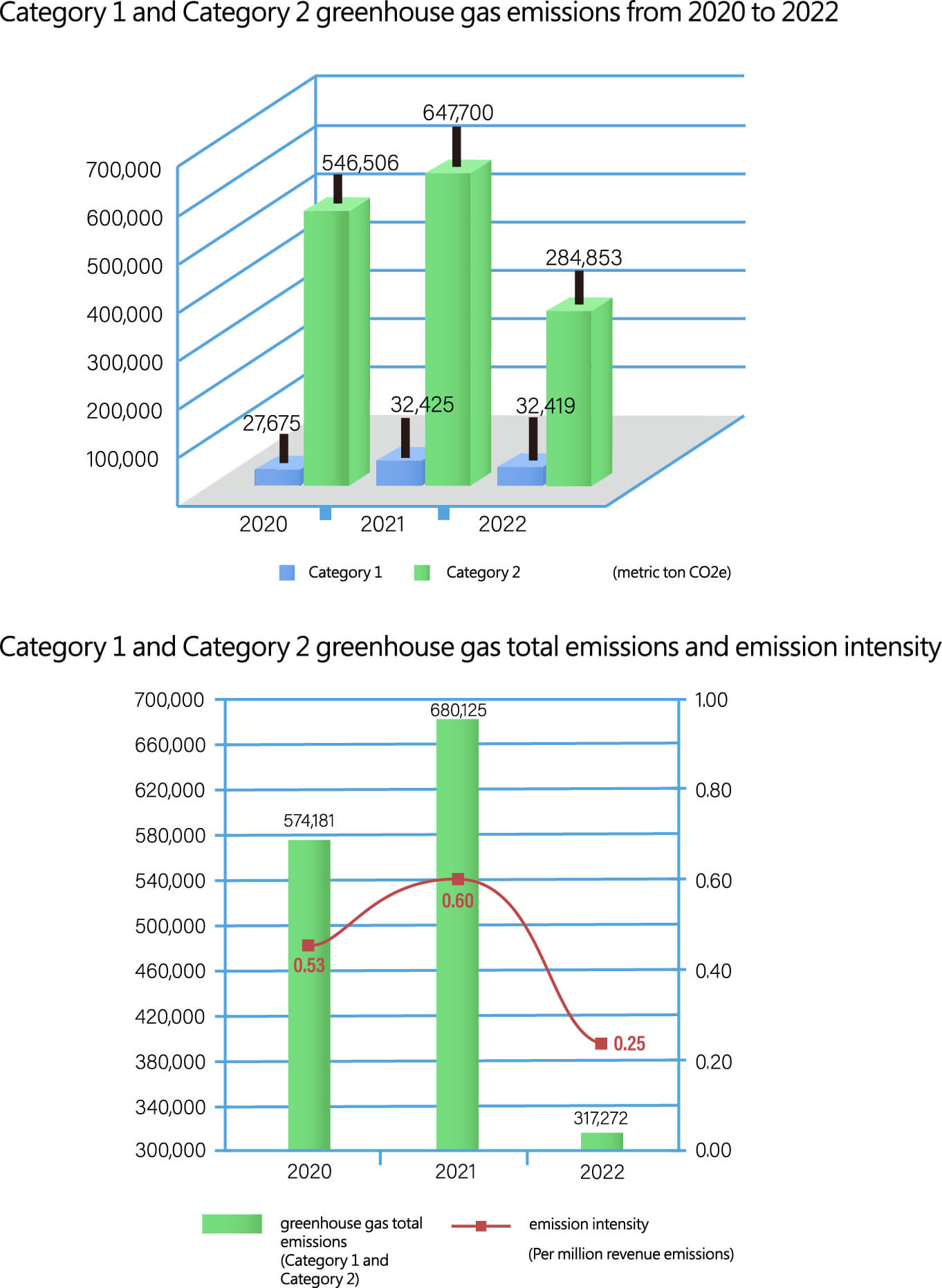

In 2022, Quanta Group expanded its factories in Taiwan and Thailand, and its revenue increased compared to 2021. However, it actively reduced carbon emissions and supplemented this with the purchase of renewable energy. The four factories used a total of 217,655 MWH of renewable energy in 2022, with a renewable energy usage rate of 25.92%. Under these efforts, compared to category 1+2 in 2021, the carbon emissions reduction reached 362,854 tons, a decrease of 53.35%. The emission intensity per million dollars of revenue dropped from 0.602 to 0.248. The presented data show that energy conservation and carbon reduction have achieved certain results.

2020 to 2022 Greenhouse Gas Emission Statistics

Greenhouse Gas Emission Reduction Target and Achievement

| Target | Effect |

|---|---|

|

|

Environmental Management System

Under the influence of global climate change, in order to pursue global sustainability, Quanta has been focusing on the reduction of production waste from the R&D and design stage, reusing relevant packaging materials as much as possible, and striving to reduce the impact on the overall environment and comply with relevant regulations.

Since 2000, each plant has been implementing ISO 14001 environmental management system and completing the certification. The continuous improvement is promoted through the Plan-Do-Check-Act (P-D-C-A) model.

By identifying the environmental considerations arising from the company's production, activities and services, evaluating the environmental considerations and their environmental impacts, and comparing their severity, we ensure that major potential factors are identified in advance, and that improvement measures and operating procedures are developed to reduce and prevent major potential impacts.

Environmental Protection Policy

Quanta Computer is a design and assembly company for professional portable computers, laptops, motherboards, and other products. The company’s main environmental impacts are effluent gas, domestic sewage, and waste materials. Quanta, in holding true to its belief of coexisting with the earth, shall undertake and are committed to the fruition of the following environmental policies to achieve the spirit of pollution prevention and continuous improvement.

- Through employee education and the implementation of ISO 14001, employees and those working on behalf of the organization are aware that environmental protection is everyone’s responsibility and obligation.

- Reduce environmental impact by decreasing both air and water pollution and waste generation.

- All products are designed and manufactured in strict compliance with applicable laws and regulations and other requirements that must be observed.

- Set environmental goals for continuous improvement.

- In achieving low-energy, low-pollution practices, factoring environmental takes product design into account.

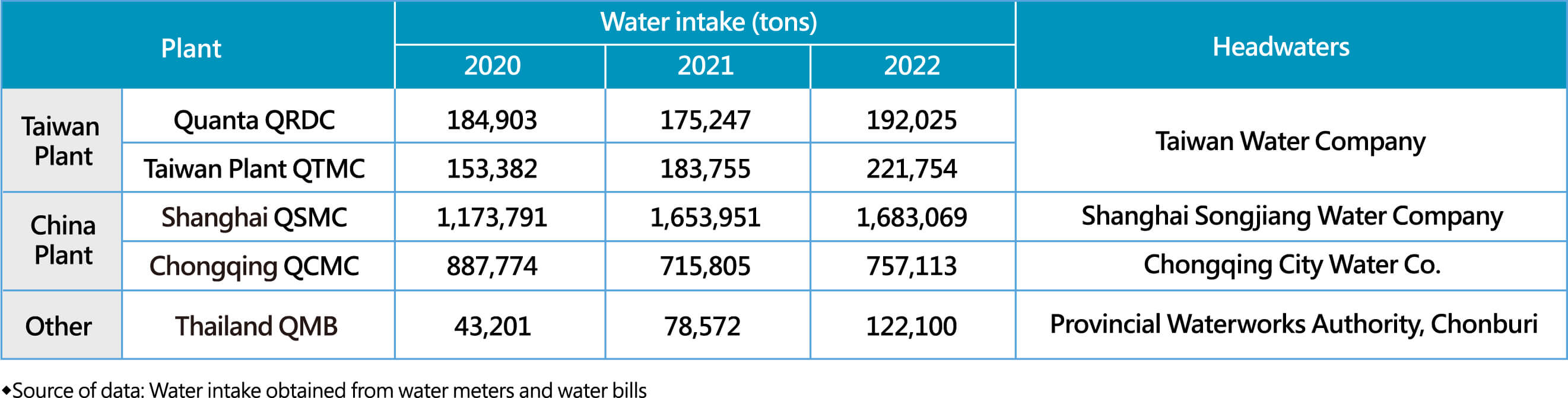

Water Resources Management

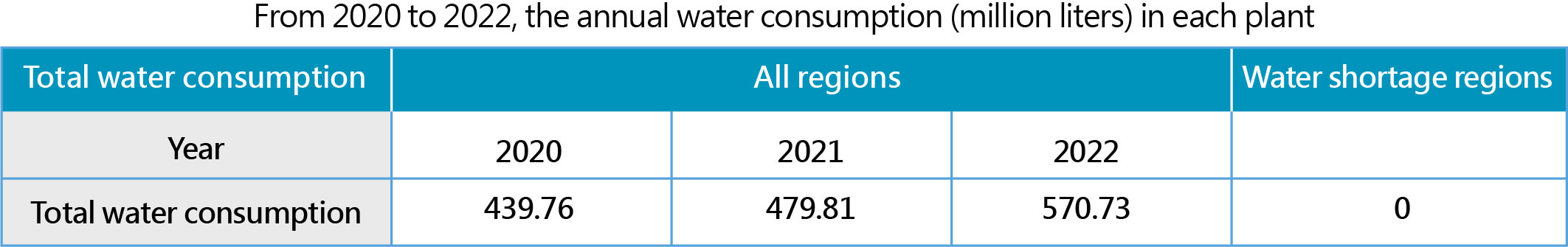

Total water withdrawal

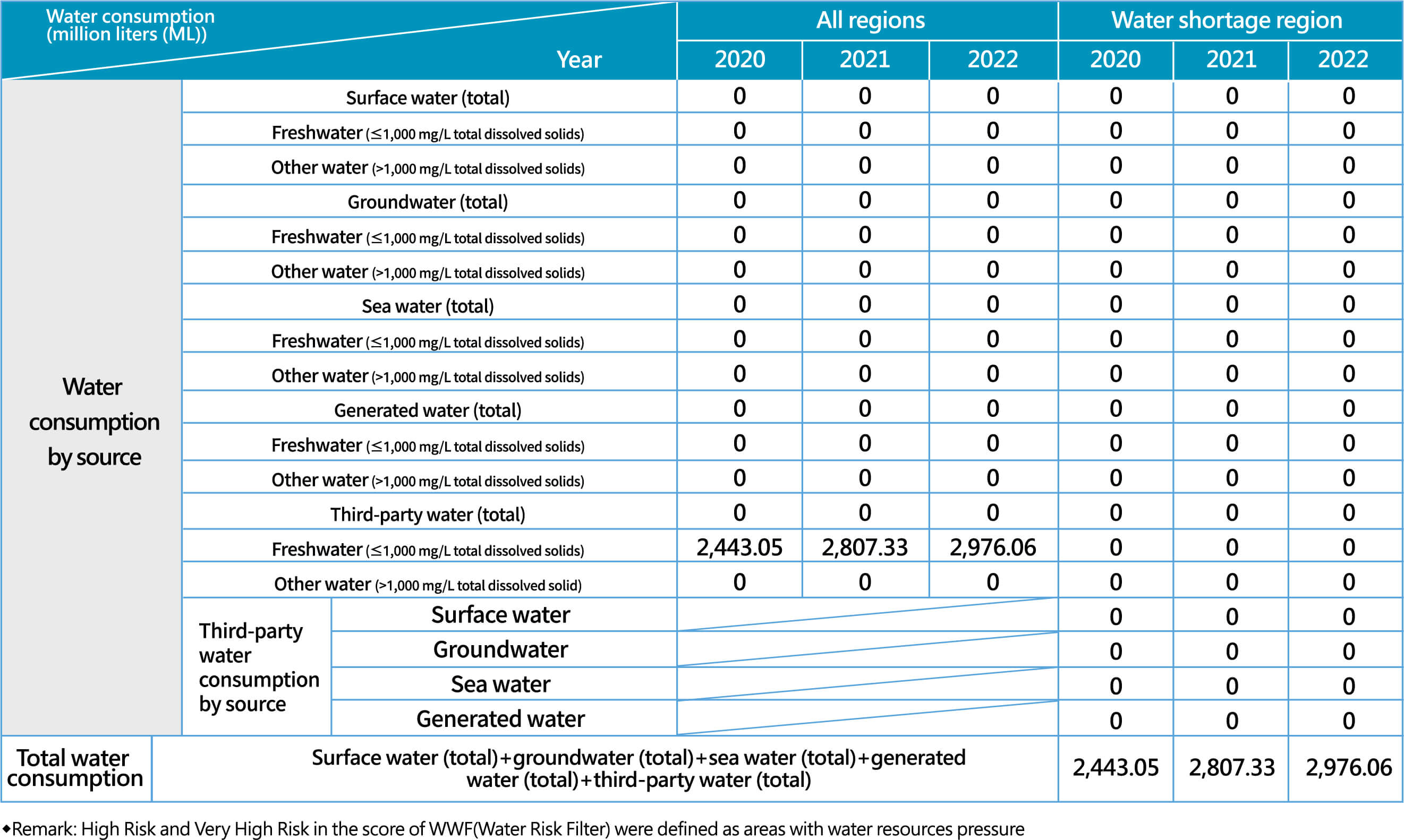

The main source of water supply is tap water, with no groundwater, rainwater storage or surface water used, and most of the uses are general domestic water, air conditioning water and kitchen water.

In order to reduce water consumption, the management unit reviews the water conservation plan and water facilities every year, and QRDC and QCMC plant toilets use sensor taps and install water saving heads to control the amount of water discharged. QRDC and Hua Ya Park Management Consultants Co., Ltd. have adopted the flood pond in the upper reaches of Nankan Creek from the Water Bureau of Taoyuan City Government to create an ecological park and achieve the goal of water conservation. QTMC QC3 is a new building with a rainwater recycling system, with 244.7 cubic meters of rainwater recycle area.

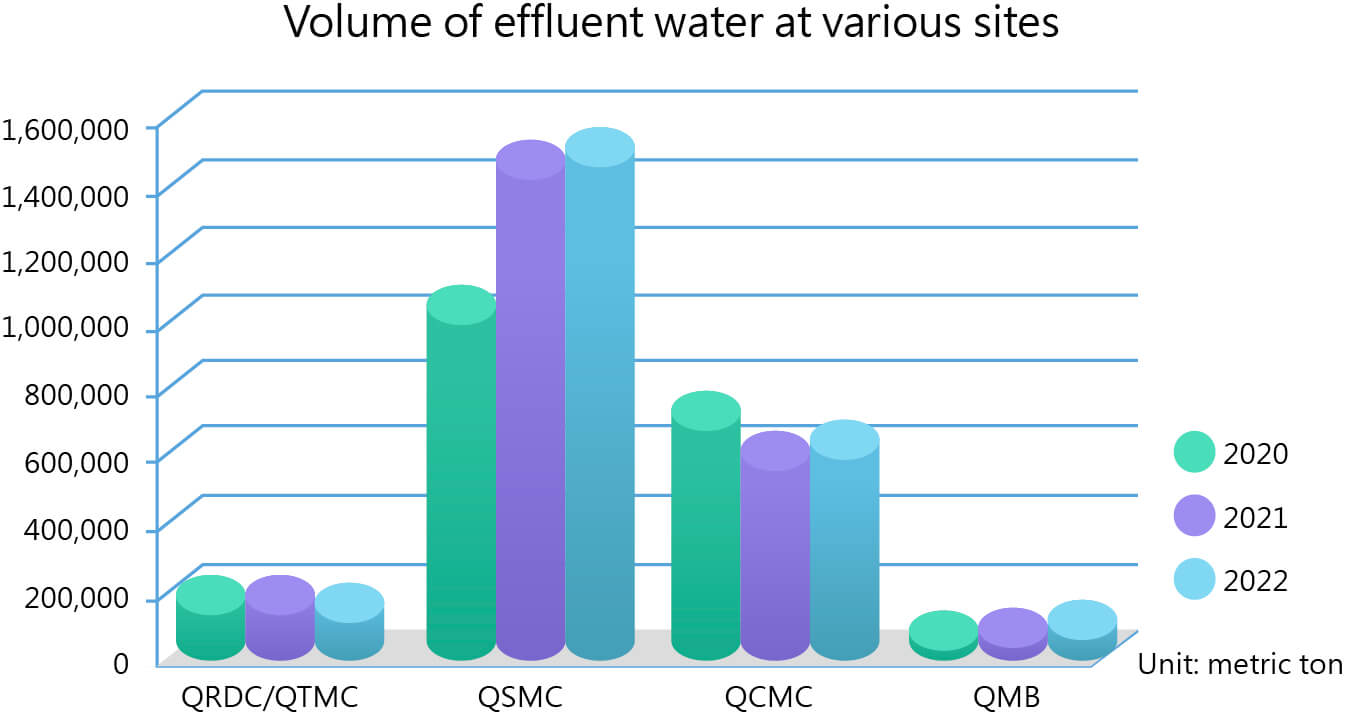

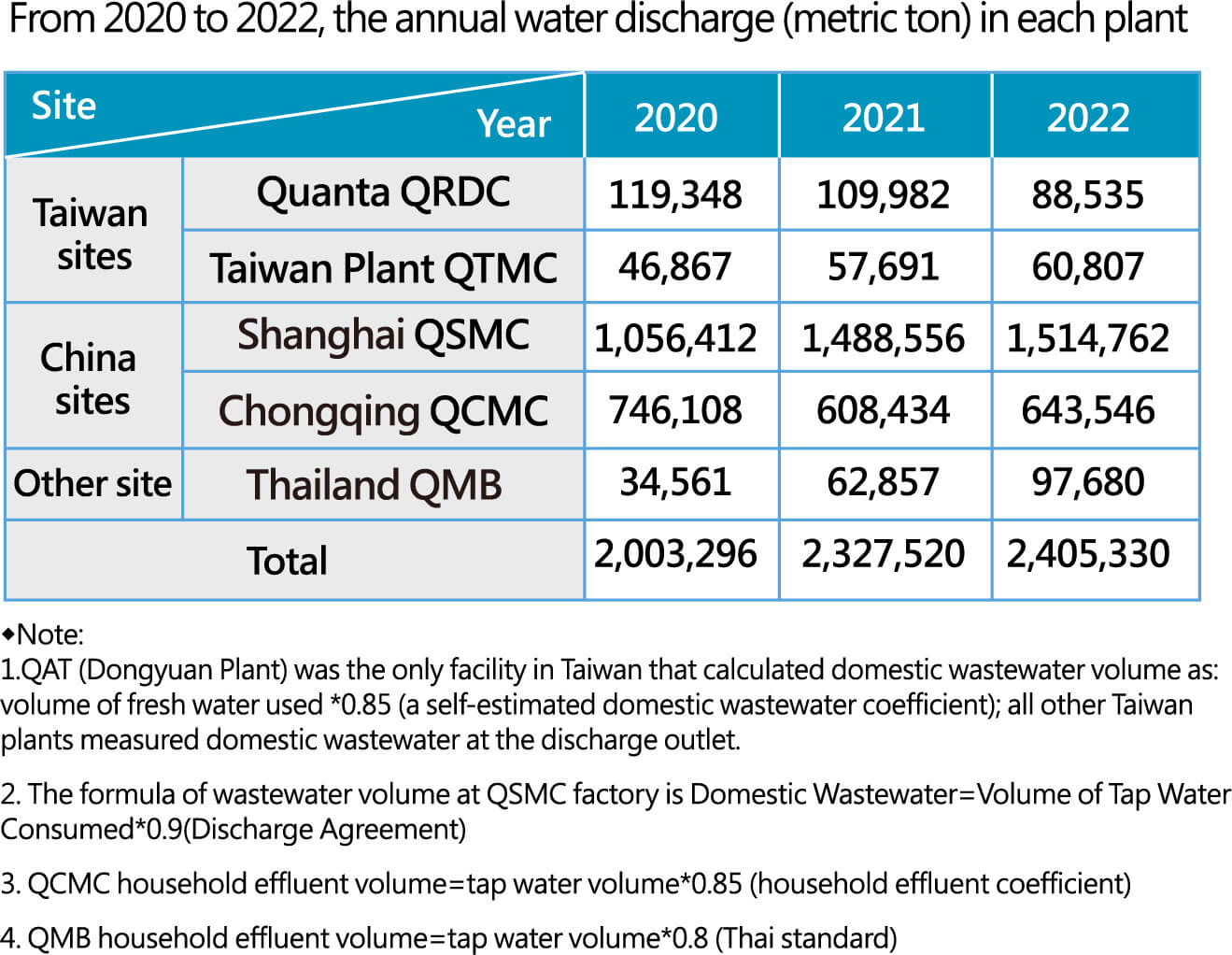

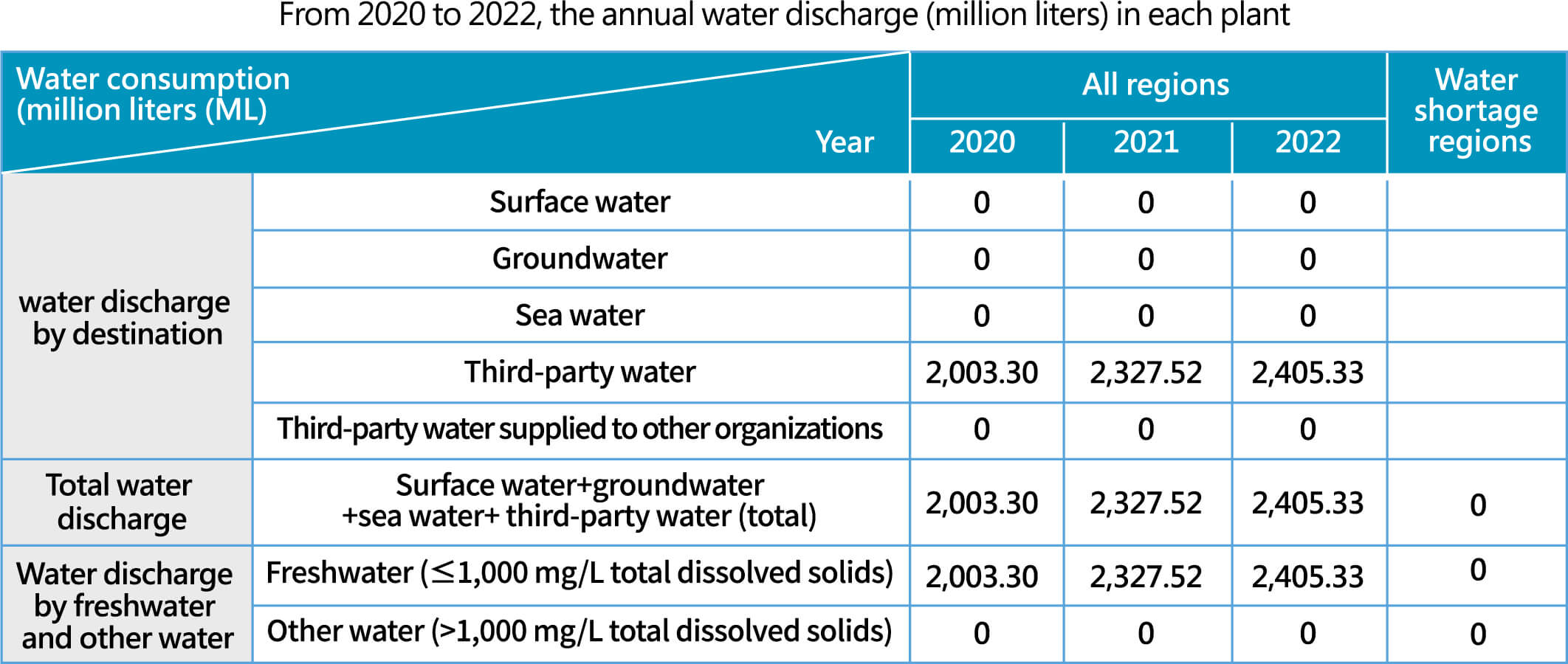

The water withdrawals for each plant area from 2020 to 2022 are shown below:

Water withdrawal by plant from 2020 to 2022 (million liters)

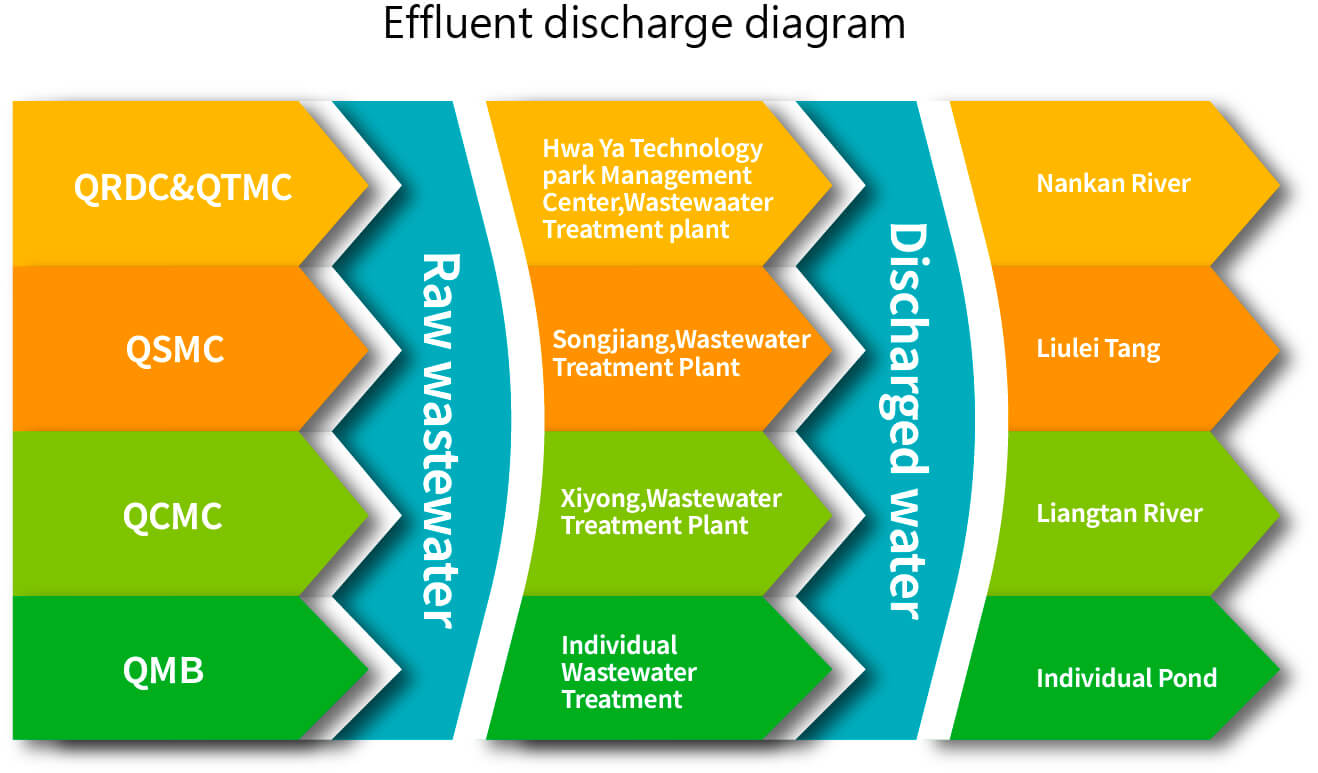

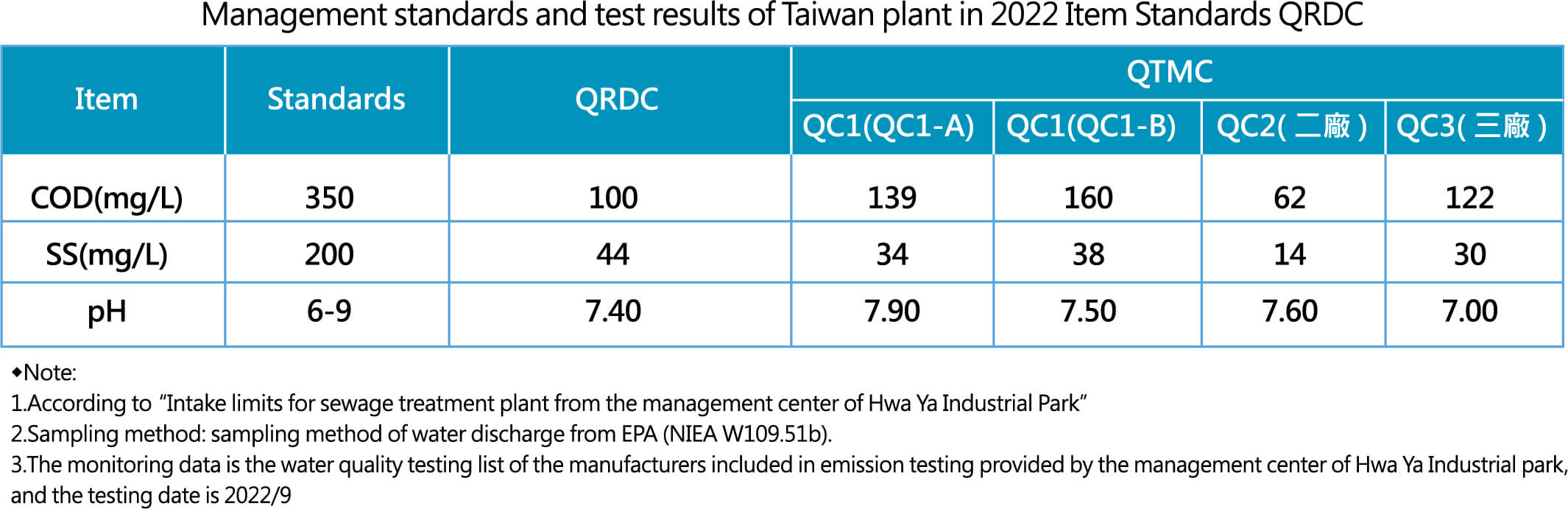

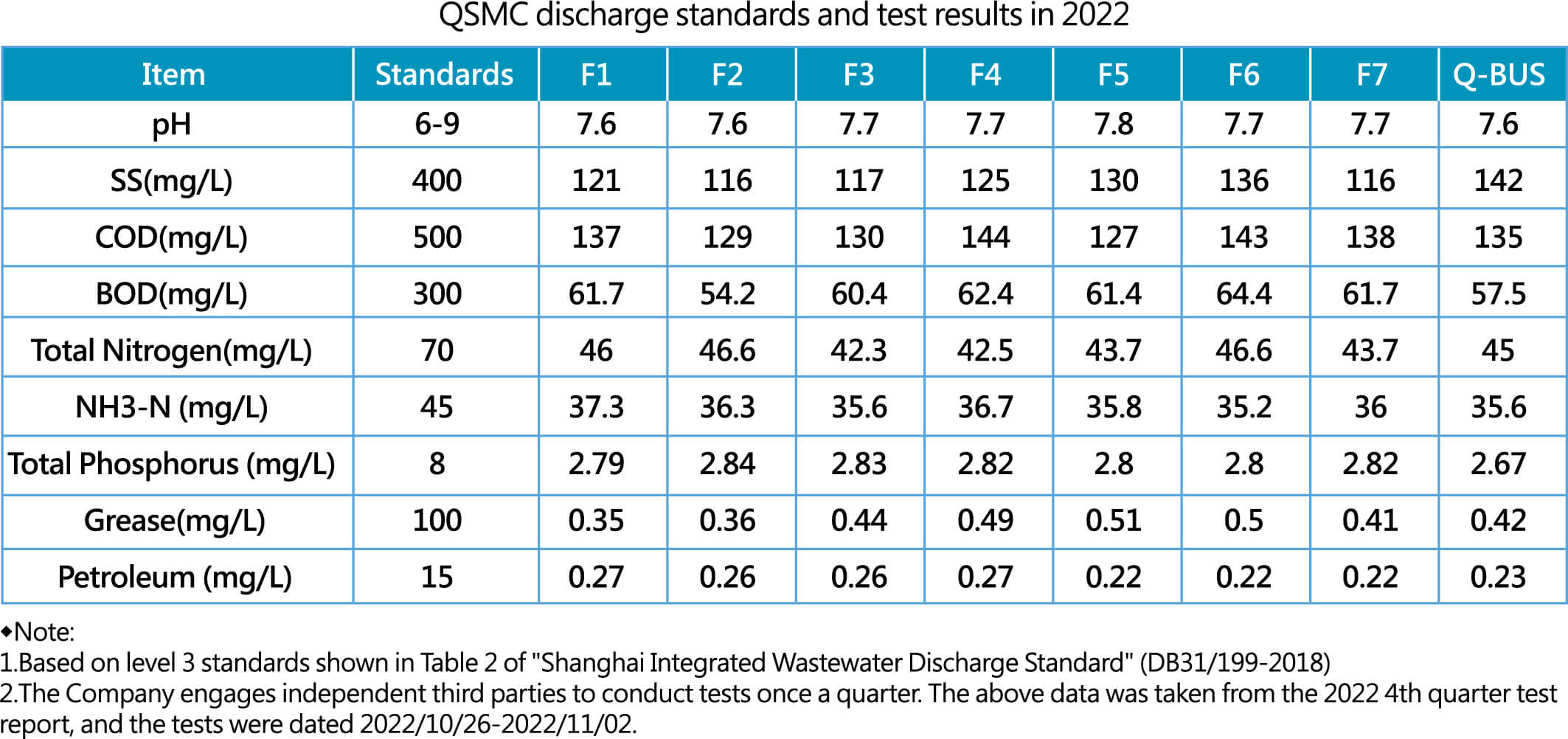

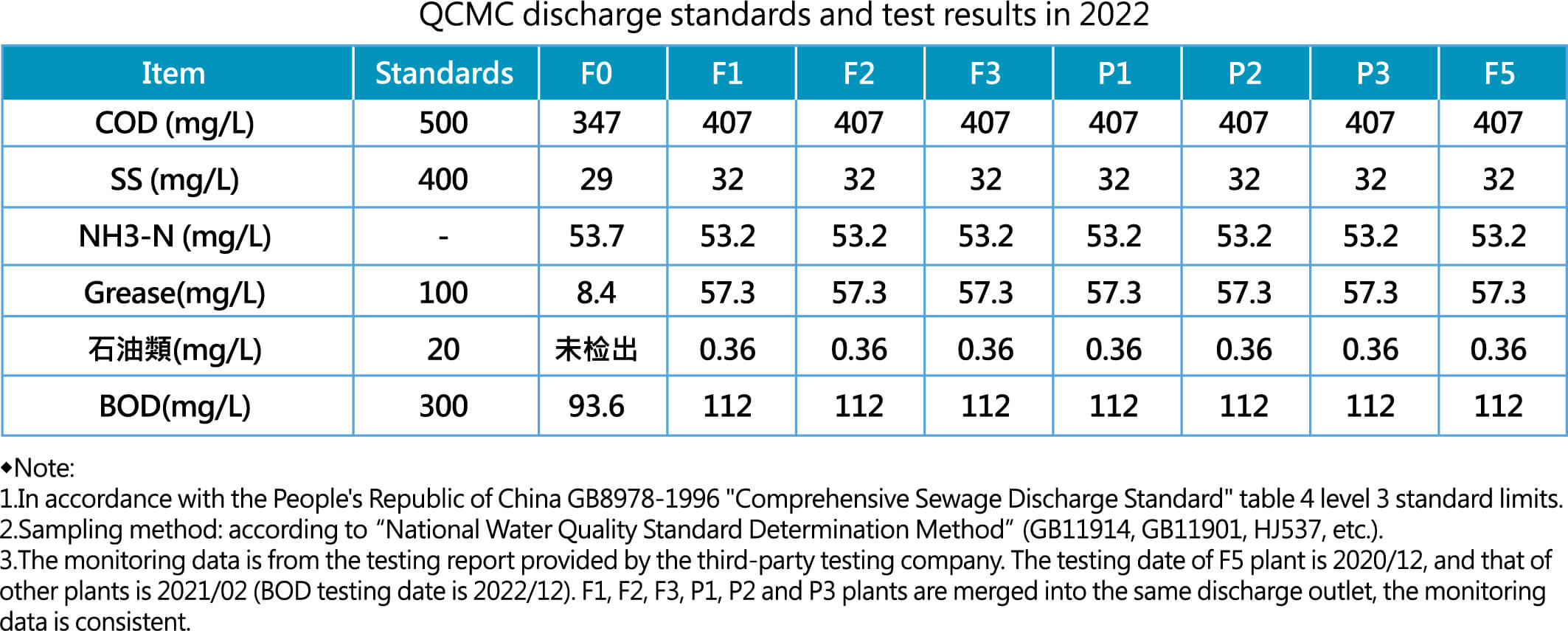

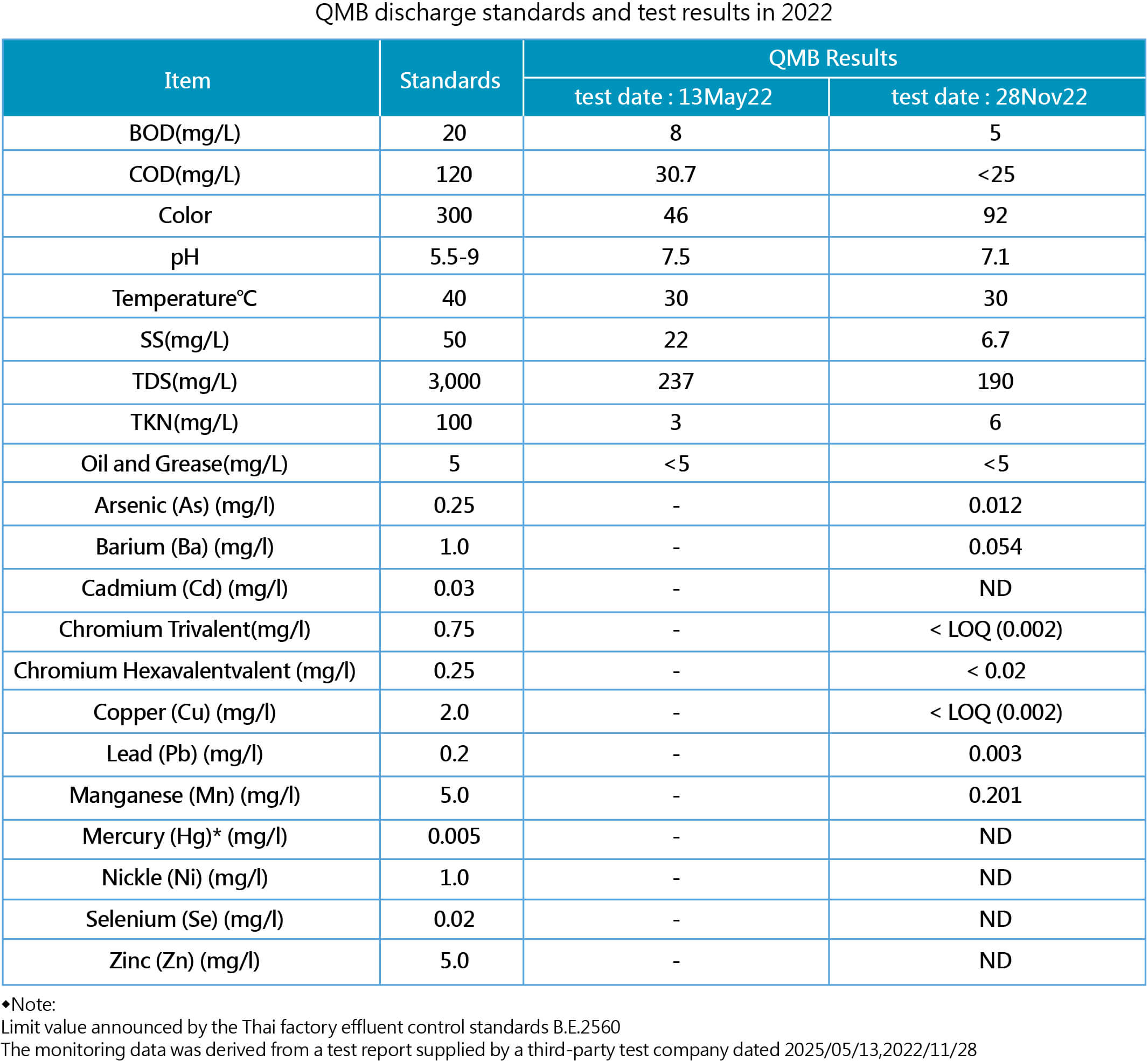

- Wastewater generated at various sites includes domestic and canteen effluent. There is no process wastewater. Hence, this Report only covers voluntary disclosures of domestic effluent within the plant.

- Domestic wastewater contains nutrients which include organic pollutants and nitrogen phosphorus, causing water eutrophication. To ensure the wastewater produced will not cause pollution to the environment, each factory is installed with primary wastewater treatment equipment. The equipment are periodically inspected and maintained to keep the systems in normal operation. To warrant that the released water quality meets the discharge standard, wastewater samples are regularly submitted to qualified testing companies for analysis

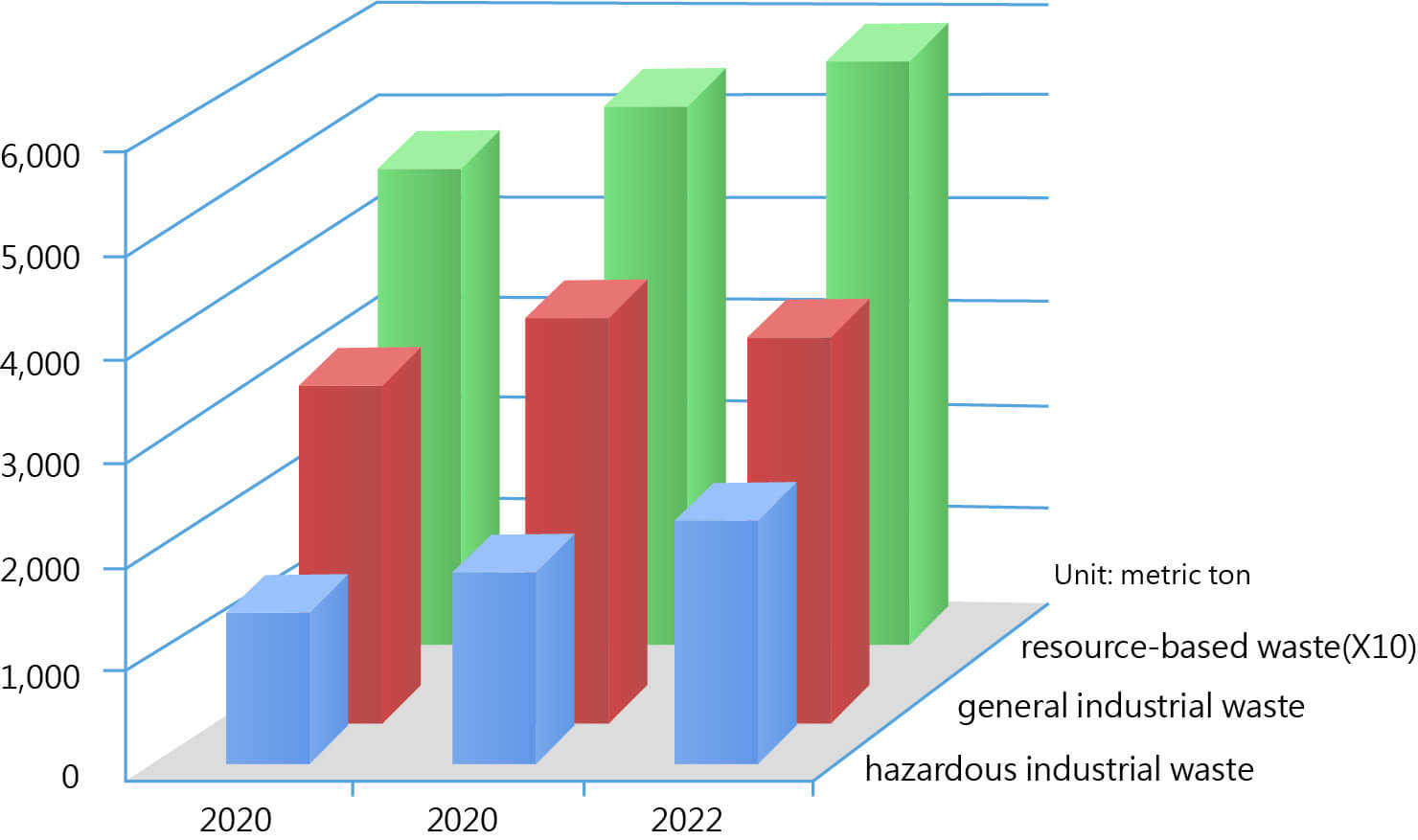

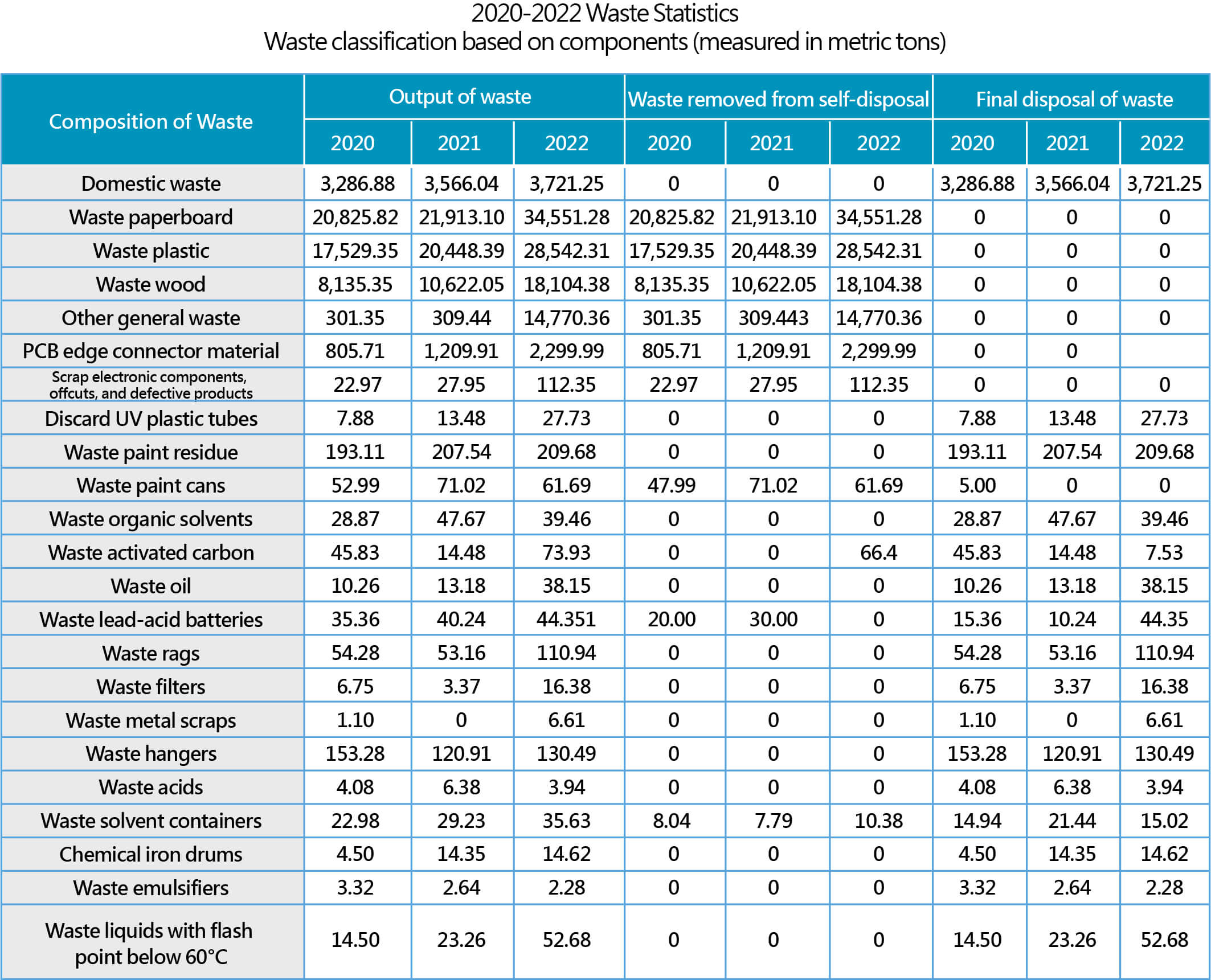

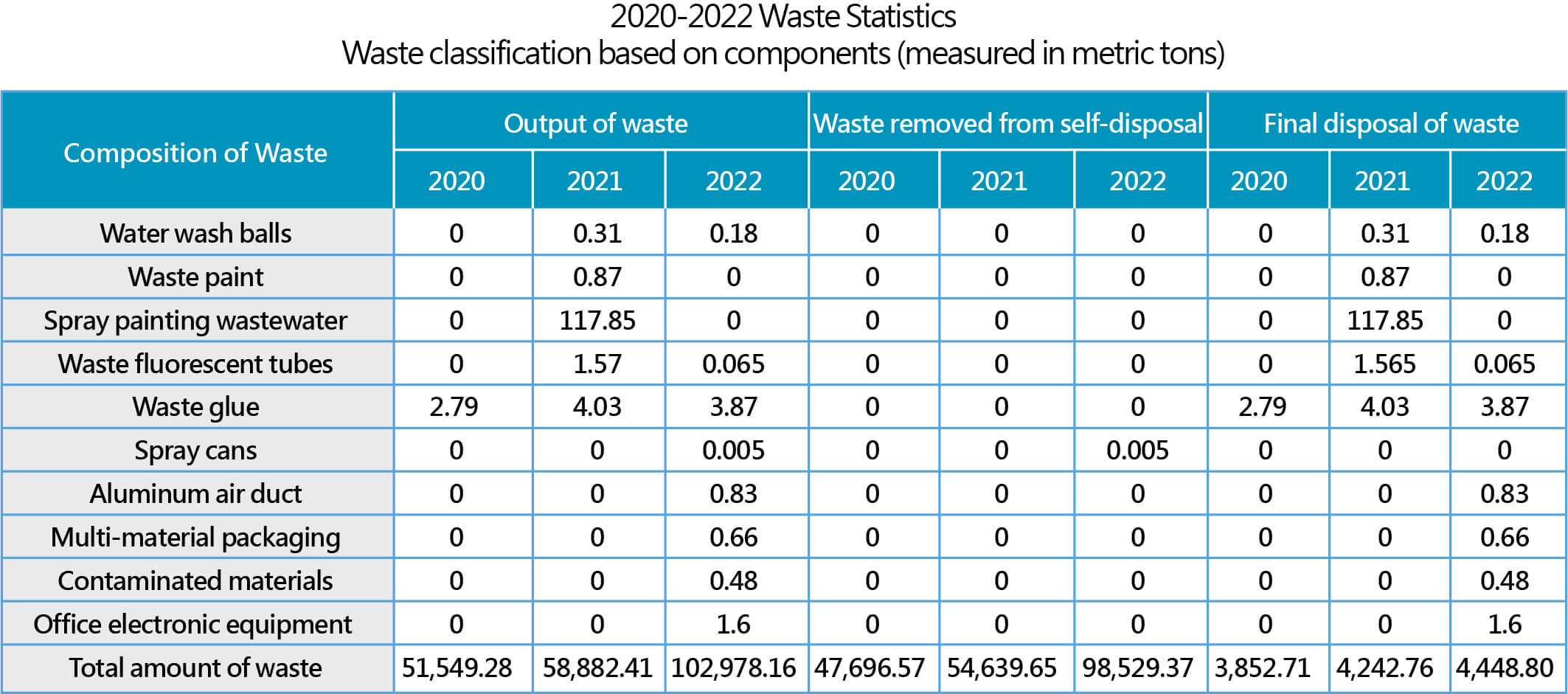

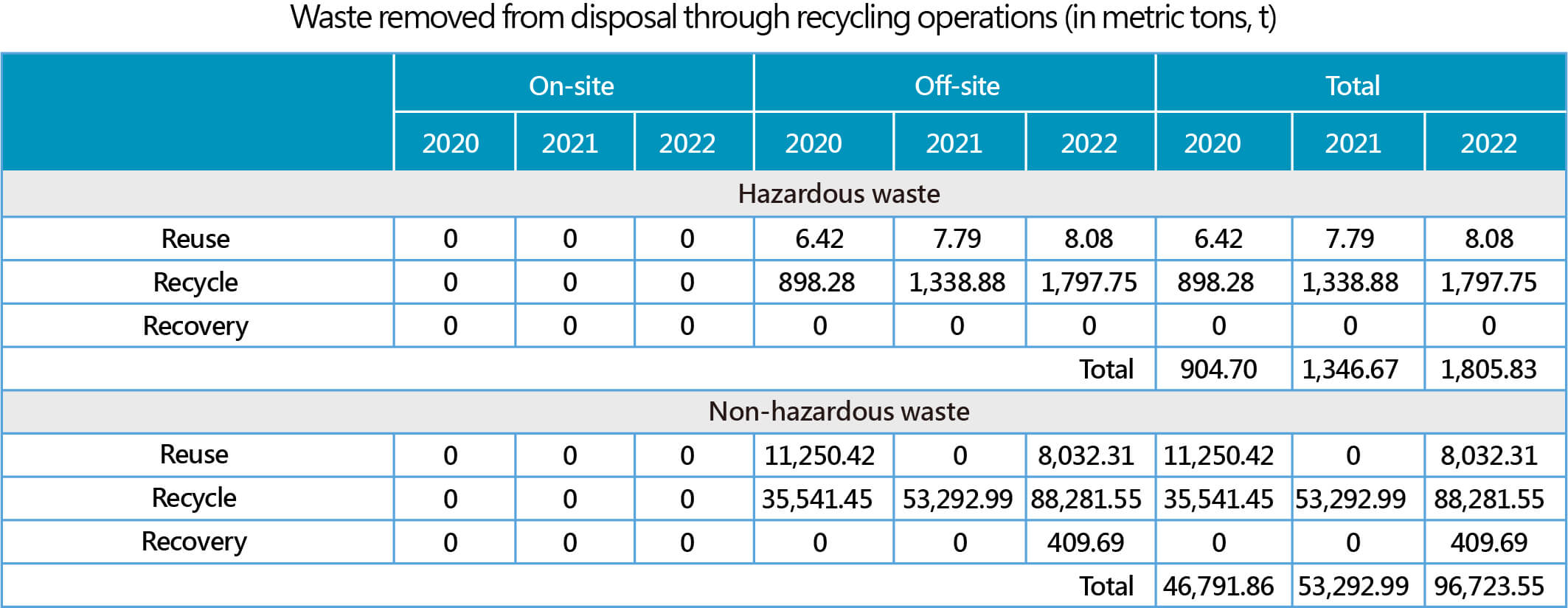

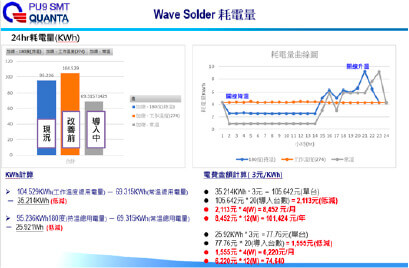

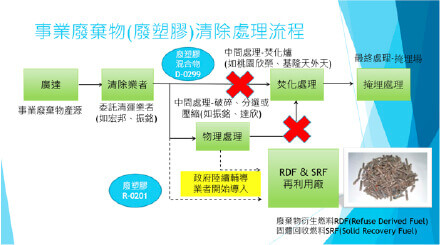

The generation of industrial waste is divided into three major types: general industrial waste, hazardous industrial waste, and resource-based waste. The company produces waste in products, events, or services, with the raw materials including many electronic components and consumables, etc. The production process generates recyclable packaging waste, of which the hazardous waste poses long-term and latent risks. If not properly handled, it will cause varying degrees of secondary pollution damage to water, soil, and air.

Quanta is committed to effective management and continuous achievement of waste reduction, with zero waste as the ultimate goal for waste management. Its collection, disposal, and recycling are all conducted in accordance with local regulations and entrusted to qualified waste removal institutions for proper handling, operation, and recording. The company's environmental protection unit conducts irregular inspections of waste disposal plants to ensure that the outsourced processing plants handle waste legally. The proportion of the three types of waste in various plants over the years is shown in the following figure (as shown below ).

To ensure waste is managed more effectively than required by law, Quanta is gradually implementing a zero-waste landfill plan in various plant sites. This program adopts the Zero Waste to Landfill (UL ECVP 2799) verification. This standard requires that all waste streams within the enterprise undergo compliance management, inspection, and auditing to ensure that waste is properly recycled, reused, and transformed rather than directly landfilled. When the overall waste conversion rate reaches 80% or higher, certification can be obtained. QTMC QC1, QCMC, and QMB have obtained platinum and silver level certifications in 2022.

Environmental Management Plan

- Previously, the pumps used in the QCMC plant area were all of IE2 energy efficiency, which is high-energy-consuming equipment.

- It is planned to replace three commonly used cooling water pumps in the F1 plant with Smart IntelliFlow high-efficiency pumps to save energy.

- The production of new models such as NJJ and NJF in the F3 plant generates a large amount of heat, resulting in a high temperature of around 44 °C inside the D/L racks. The heat cannot dissipate properly, causing abnormal computer downloads.

- By utilizing RF heat exhaust, the internal heat of the D/L racks is expelled outside, achieving cooling and energy-saving effects.

Compliance with environmental protection regulations

There were no major violations of environmental regulations by Quanta in 2022.

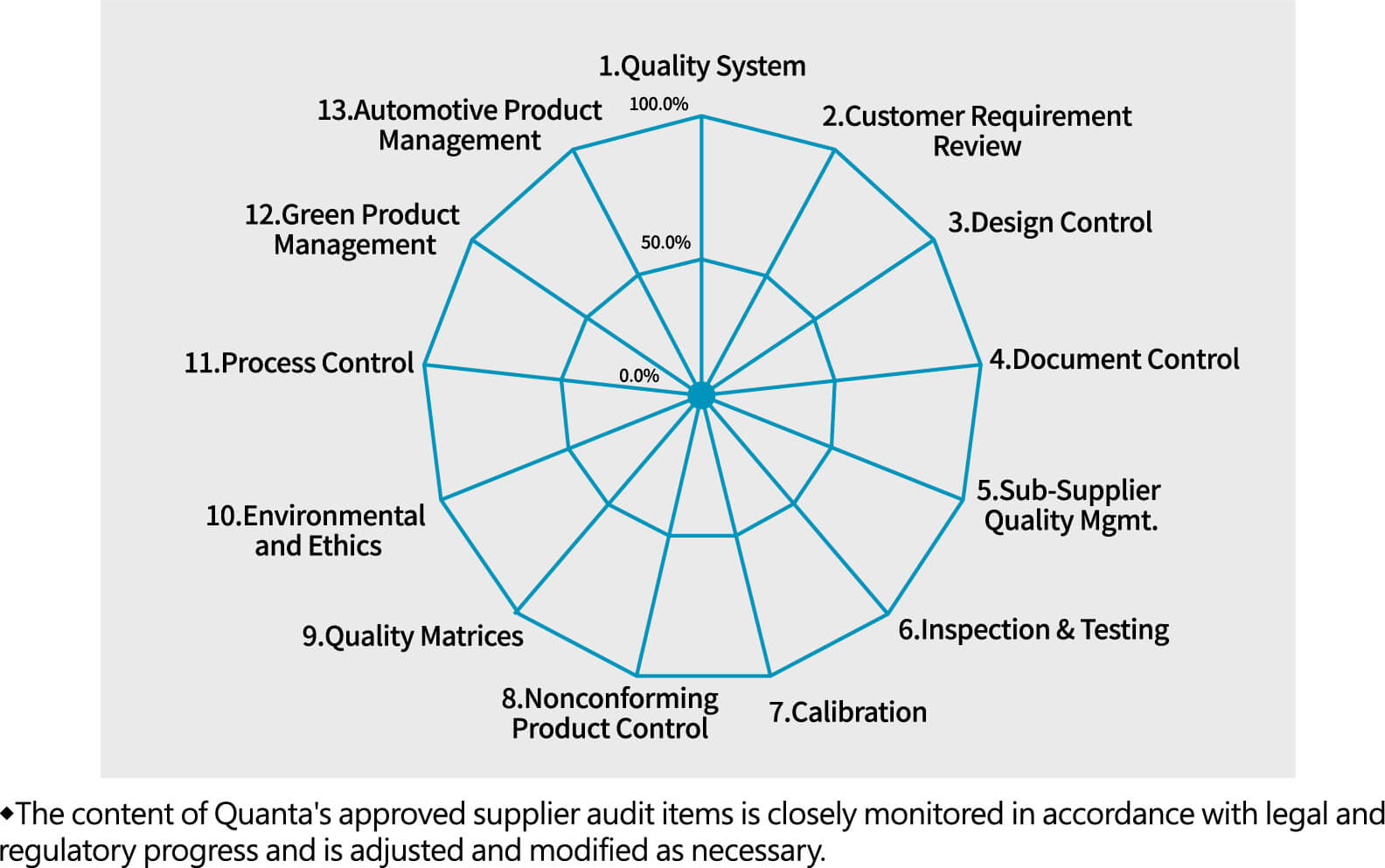

Quanta Computer designs and produces environmentally friendly green products to protect the environment and improve people's quality of life. Our green product strategy is to incorporate the concept of sustainability into the entire life cycle of design, production, packaging, transportation, use, and recycling of our products. This includes using eco-friendly materials, energy efficiency, pollution reduction, recycling, and reuse to minimize the impact of e-waste on the environment.

Product Research and Development Design

Quanta has long been investing in the research and development of green products and is implementing green design in the following six aspects:

- Product material and chemical composition control

Introducing a Full Materials Declaration (FMD) management system to identify potential hazardous substances in product components and reduce the risks to human health and the environment.

- Establishment of a product recycling material evaluation tool

The design team conducts regular life cycle assessments to effectively evaluate the recyclability and proportion of recycled materials in products to determine their impact on the environment. We continuously optimize the production and usage processes and ensure that products can be recycled and reused to meet international legal and design requirements. Quanta follows the Waste Electrical and Electronic Equipment Directive (WEEE) and designs products that are easy to disassemble and recycle. All products developed in 2022 have been certified according to WEEE regulations and marked with the WEEE recycling logo. According to the WEEE recycling logo standards, the percentage of recyclable materials used is estimated to be over 80%.

- Improving energy efficiency

In addition to using a large number of low-power electronic components, introducing energy-saving modes, and providing energy management solutions, our products have passed strict tests to ensure compliance with national and international standards. Every year, hundreds of products are certified with international certification logos such as EnergyStar, MEPS, CEC, and e-Standby. The performance of Quanta's products in terms of operation, standby, shutdown, and battery charging and discharging efficiency far exceeds international standards.

- Expanding the use of sustainable materials

In terms of green design and the use of sustainable materials in products, the "3 R's (reduce, reuse, and recycle)" are the core principles dedicated to the full utilization of various energy resources. During the green design phase of products, low-environmental-impact as well as recycled and regenerated materials are introduced into the products. For example, using "post-consumer recycled plastics, ocean-bound plastics, and recycled metals" to make product components promotes the development of a circular economy, reduces the use of energy resources, and produces environmentally friendly products. Thus, we achieve sustainable resource recycling and address the issues of resource scarcity and excessive waste.

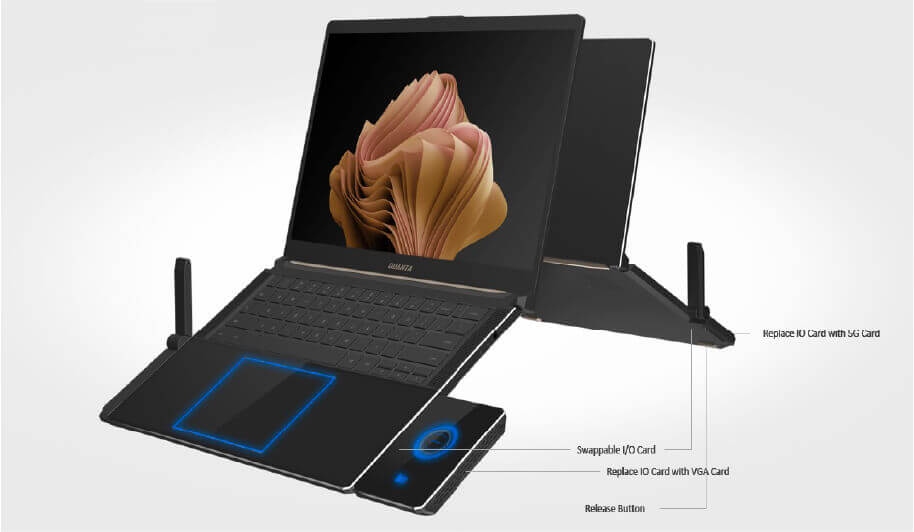

- Modular design

Quanta focuses on durable and easy-to-maintain modular design, providing customers with the needs for self-maintenance, replacement of parts, and upgrades, which can extend the product life cycle. We promote the use of shared components and modules to reduce the indirect consumption of resource materials during development.

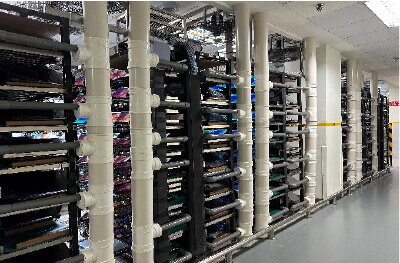

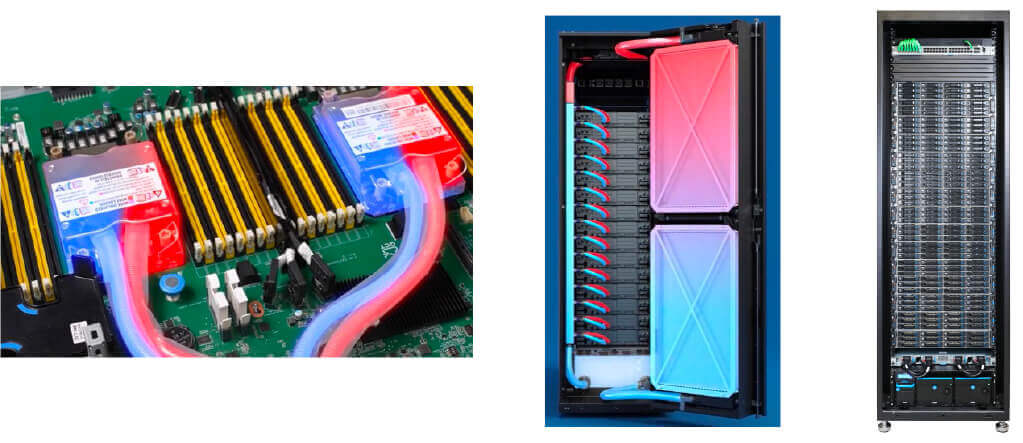

- Energy-saving and cooling technology development

Active research and development efforts are being made to introduce liquid and air-cooling technologies in large server racks and data center products. The QoolRack liquid-cooled server cabinet design has been launched, which offers a solution that is both flexible and scalable, with excellent cooling performance, for systems equipped with high-power CPUs. This design can significantly optimize power usage efficiency (PUE), achieving a lower total cost of ownership over the entire system life cycle compared to traditional air-cooled cabinets.

Green indicators

Patents, innovative designs, and sustainable product certification demonstrate Quanta Computer’s investment and achievements in promoting sustainable design.

- Patent achievements

In 2022, a total of 5 ESG-related patents were granted, demonstrating Quanta’s investment and achievements in sustainable design through innovative technology research and development throughout the product life cycle, including design, production, packaging, use, and recycling.

- Innovative design

We heavily invest in innovative eco-friendly designs, such as the MP8 multi-module computer. This is a groundbreaking computer design prototype that has received recognition for multiple invention patents and significantly outperforms various environmental sustainability indicators. It is considered the best information product in the industry within the past five years.

- Shared modular core design: The shell can be installed on tablets, PCs, and AIOs, greatly increasing product usability, extending product lifespan, and reducing resource consumption from producing multiple different machines. This is an innovative product designed for ESG-friendly environments and circular economy goals.

- Full-range interchangeable performance components: 5G, GPU, storage, and IO can be replaced according to needs without purchasing a new product, reducing WEEE electronic waste by up to 60%.

- Adopting high-quality recycled plastic and metal with a detachable IO design: reducing the carbon footprint of resource extraction by up to 20%.

- Ultimate energy-efficient design with Energy Star, ErP, and CEC: reducing product energy consumption by up to 50%

- Sustainable Product Labeling

Product research and development actively incorporate international sustainable labeling requirements and energy efficiency design, such as Energy Star, EPEAT, and TCO sustainable certification.

The EPEAT environmental label is one of the most rigorous product environmental standards globally. Its standards include material management, raw material selection, life cycle design, extending product life, saving energy, end-of-life management, product packaging, life cycle assessment, carbon footprint, corporate environmental performance, corporate social responsibility, and ten other aspects. The focus is on reducing the impact on the environment throughout the entire life cycle.

TCO verification aims to promote the sustainability of social and environmental factors throughout the entire product life cycle. Its standards include product sustainability, socially responsible manufacturing, environmentally responsible manufacturing, user health and safety, product performance, extending product life, reducing hazardous substances, material recycling, and eight other aspects. The focus is on environmental and social responsibility in the supply chain and the entire IT product life cycle.

The following is the number of environmental label certifications obtained in 2022:

- Life Cycle Assessment (LCA)

Some products have adopted life cycle assessment, collecting data on product life cycles such as raw materials, production, transportation, use, and recycling, evaluating the product's impact on the environment throughout the entire life cycle, such as greenhouse gas emissions, energy consumption, and water consumption, and evaluating methods to improve the product.

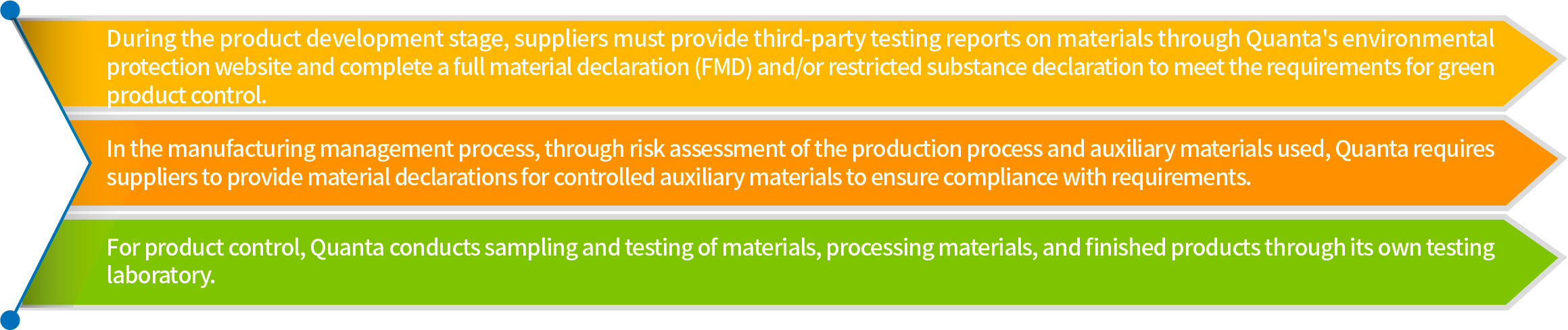

Control of toxic and hazardous substances

Quanta follows the ISO 9001:2015 and QC 080000:2017 standards published by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), respectively, and links the control processes of toxic and hazardous substances in research and development, procurement, manufacturing, and customer service to ensure that all products meet the requirements of being free of harmful substances.

Our goal is to ensure that 100% of our shipped products meet customer and regulatory requirements, as well as customer-specific requirements for green products, with a 100% on-time rate for new product launches.

To achieve effective control, Quanta has established GP laboratories in Taiwan, China (Shanghai and Chongqing), Thailand, and other factories. Testing methods are based on IEC 62321 and international inspection standards. Materials, process materials, auxiliary materials, and finished products are tested for harmful substances such as the RoHS Directive, packaging directive, Toxic Substances Control Act (TSCA) in the United States, and halogens (chlorine, bromine), in accordance with regulations and customer requirements. The testing equipment and corresponding items at Quanta's Green Product Laboratory are as follows:

In 2022, a total of over 10,000 samples of raw materials, process materials, auxiliary materials, and finished products were randomly selected and tested.

Achievements in 2022

Customer satisfaction

Every year in the fourth quarter, Quanta conducts a customer satisfaction survey through the "Customer Satisfaction Survey System" to actively obtain customer feedback and use it as a direction for continuous improvement.

Based on the results of the 2022 customer satisfaction survey, which includes quality management and green product management, the percentage of customers satisfied with Quanta remained largely unchanged compared to 2021. Whenever customers provide feedback and suggestions for improvement, Quanta immediately conducts a root cause analysis and implements improvement measures. At the annual management review meeting, the results of the customer satisfaction survey from each business unit are reviewed, and the various survey indicators are analyzed to identify improvement directions. This serves as a reference for enhancing ESG and setting targets for the following year.

Overall Background of the Supply Chain

Quanta is a research and manufacturing company for electronic products. Based on customer demands, products are designed or assembled into finished goods and then delivered to designated areas for sale.

The main supply chain consists of electronic or mechanical component suppliers for major products such as notebooks and servers. The supply chain is largely composed of domestic and foreign suppliers with advantages in these types of goods. The estimated number of raw material suppliers exceeds 2,000 companies, primarily located in Taiwan, the United States, Japan, South Korea, China, and Europe. Supplier types include original manufacturers, authorized agents, and distributors. Specific industry characteristics of the supply chain include capital-intensive, technology-intensive, and labor-intensive aspects.

Supply chain strategies are primarily based on competitiveness, including price, research and development capabilities, manufacturing capabilities, quality advantages, shipment process management, on-site service, etc. Changes in supplier relationships during the reporting period are normal operational aspects of strategic nature, without any other significant changes due to specific factors.

Strategies and Goals of Supply Chain Management

Management Strategies and Goals

Business transactions involve assessing whether suppliers have a record of impacting

the environment and society. If suppliers are found to be involved in policy

violations and have a significant impact on the environment and society in the

source region, it may be necessary to terminate or dissolve the contract terms.

Early Warning Policies and Practices

By establishing a composite supply chain and conducting periodic factory visits and

audits, timely audits of relevant suppliers are carried out when major occupational

safety accidents and environmental issues occur in specific regions or industries.

Periodically, key suppliers are also required to undergo audits based on the

relevant behavior guidelines of the RBA to assess whether their performance on

various corporate social responsibility issues may pose risks to the company's

operations.

Supplier Management Guidelines

Selection System

Suppliers are important business partners and quality-related stakeholders for

Quanta. Their compliance and conformity with environmental practices, labor

practices, human rights, social impacts, and local legal and regulatory aspects will

directly or indirectly impact Quanta's operational stability, product quality,

delivery time, and corporate reputation. Therefore, we have implemented a rigorous

set of supplier management guidelines for screening and audit management. The

selection of new suppliers emphasizes the importance of environmental compliance,

ethical regulations, and green product management, which are indispensable criteria

in the evaluation.

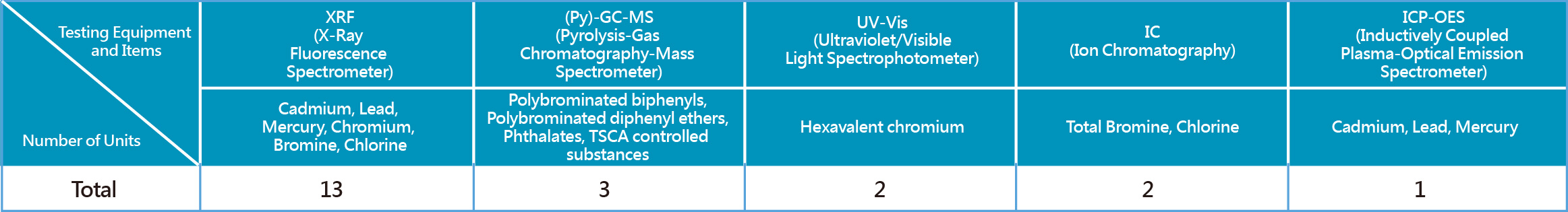

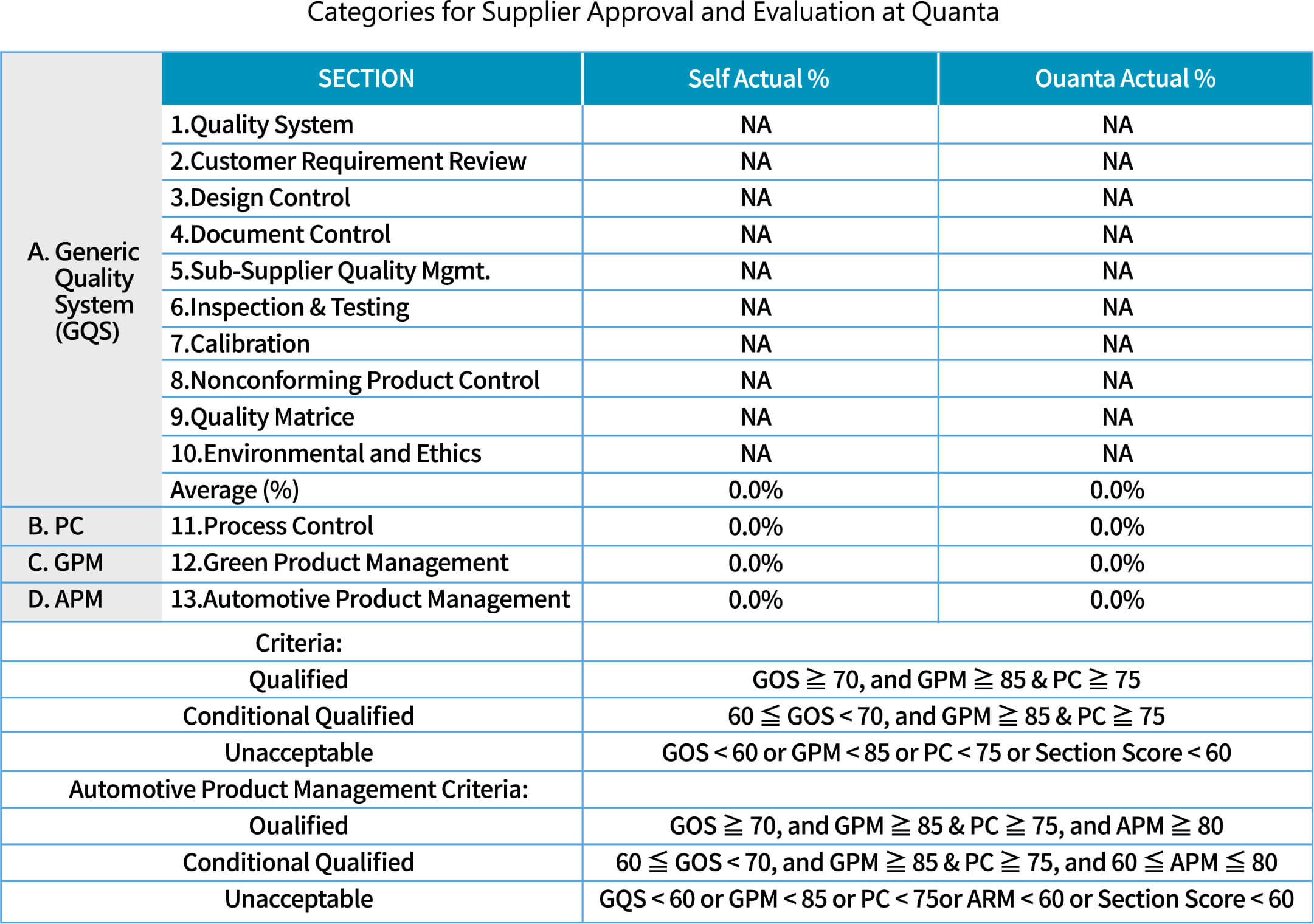

Approval Standards

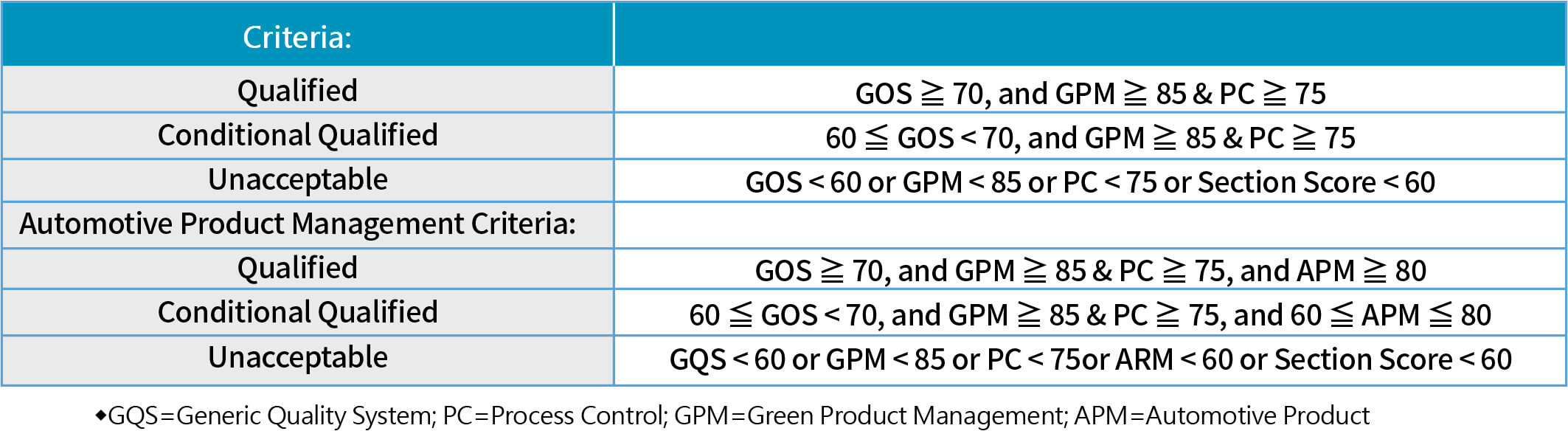

Management; APM = Automotive Product Management. The standards are adjusted based on customer requirements and changes in laws and regulations. The approval standards for 2022 remain the same as those of 2014, with the addition of automotive product audit items and approval standards.

Guidelines and Impact of Evaluation Results Management

The evaluation results are communicated through direct audits, reviews, and indirect two-way participation. Once an audit report is issued with an SCAR (Supplier Corrective Action Report), the supplier is required to respond with relevant improvement plans or outcomes within the specified deadline. If there are evaluations that involve longer time frames for assessing improvements, such as charter modifications or equipment purchases, they will be discussed separately. Actions for overdue responses may include returning items or terminating the cooperative relationship.

Additionally, if a supplier does not pass the approval standards in the audit, the purchasing system will be incapable of placing orders. Through the evaluations, it has been determined that no suppliers employ child labor or engage underage workers in hazardous or high-risk work. No suppliers with forced or compulsory labor risks have been identified. However, if during the audit process a supplier is found to be in violation of labor rights and ethical standards and is unable to improve within the given time frame, they will be rejected and cannot become an approved supplier of Quanta.

Proportion of On-site Audits for New Suppliers

Quanta conducts on-site audits for general new suppliers based on environmental, labor rights, ethical standards, and social impact criteria, as well as engaging in two-way participation investigations for other suppliers. As of the end of 2022, the proportion of new suppliers that have undergone on-site audits and two-way participation investigations is 100%. In 2022, the compliance rate of new suppliers undergoing on-site audits under the supplier management guidelines was 100%.

Annual CSR management for suppliers

Quanta requires suppliers to fully comply with RBA guidelines and sign a declaration of RBA compliance. In order to understand the CSR performance of key suppliers, 124 CSR questionnaires were distributed to them. Through their responses, the execution and potential risks of suppliers in terms of corporate responsibility were confirmed and further tracked.

RBA audit

Quanta conducts CSR risk identification and classification based on its suppliers' geographical location, industry characteristics, and procurement methods annually, according to the decision of the Corporate Governance and Ethical Norms Subcommittee under the Sustainability Development Guideline Committee. As a member of the RBA Responsible Business Alliance, Quanta also uses RBA regulations as a basis for managing suppliers and conducts annual CSR audits of important suppliers.

In 2022, a total of 63 supplier audits were completed, and 37 service providers were audited, with the main shortcomings being working hours, no forced labor, wages, and benefits. Improvement plans have been requested from suppliers, and their progress is being tracked.

Overall, in 2022, the audit results of higher risk suppliers did not reveal the use of child labor or other significant human rights violations.

Overview of international trends and customer requirements

For the Democratic Republic of the Congo and its neighboring countries, non-governmental military groups control the mining, transportation, and trading of minerals such as gold (Au), tantalum (Ta), tungsten (W), tin (Sn), cobalt (Co), mica, and other minerals. These activities have led to social, environmental, and human rights issues in conflict-affected and high-risk areas. The international legislative trend, the investigation of the mineral source by brand customers, and the reporting requirements of smelters are also increasing, including efforts to require suppliers to achieve 100% investigation and for smelters and refiners to be 100% certified through independent third-party auditing.

From the perspective of international industry trends, RMI and customers have clear requirements for due diligence and risk management for two minerals in the supply chain: cobalt and mica.

Responsible Mineral Procurement Policy of Quanta

- Our company recognizes that mining, trading, processing, and exporting gold (Au), tantalum (Ta), tungsten (W), tin (Sn), cobalt (Co), mica, and other minerals in conflict-affected and high-risk areas may pose significant negative impacts and that companies have a duty to respect human rights and not contribute to conflicts. Our company adopts and widely promotes a responsible mineral procurement policy for conflict-affected and high-risk areas and commits to refraining from providing financial support for any activity that could cause social, environmental, and human rights deterioration.

- As a member of RBA/RMI, our company performs due diligence investigations on responsible mineral procurement in accordance with the OECD Due Diligence Guidance for Minerals, RMI frameworks, and customer requirements. We also regularly monitor the RCOI mineral origin information published by RMI to assess related risks in the Democratic Republic of Congo and neighboring countries and/or other high-risk areas. Our company requires smelters/refiners in the upstream supply chain to actively participate in independent third-party certification programs (RMI/LBMA) and requires suppliers to engage in responsible procurement from smelters/refiners that comply with RMI/LBMA certification. At the same time, we support the continued use of conflict minerals from the Democratic Republic of the Congo and its neighboring countries and/or other high-risk areas that have been certified by independent third-party certification programs so as not to affect or reduce responsible mining operations in these areas.

- Our company continues to support the OECD Due Diligence Guidance for Minerals and RMI strategies and practices for responsible mineral due diligence investigations, using RMI's due diligence investigation report templates and supporting management tools, and designating responsible units to establish effective management programs. We consistently communicate our responsible mineral procurement policies to suppliers, provide responsible mineral procurement training to suppliers, and investigate the implementation of our company's policies by suppliers, taking relevant measures to reduce and/or eliminate risks

Overview of Quanta's 2022 Due Diligence Investigation

- Preparatory Stage

- The company has a large group of suppliers, and to make its responsible mineral sourcing due diligence more efficient, the company has done a lot of preparatory work in the early stages of the investigation, including: identifying the target of the investigation, verifying the contact information of the investigation targets, identifying the internal procurement responsible persons corresponding to the investigated suppliers, and upgrading and optimizing the responsible mineral procurement management system.

- On top of expanding the scope of cobalt metal supplier investigation in 2021, our company added the identification of all possible mica material suppliers to be investigated in 2022.

- Investigation Stage

- The CAMP system sends due diligence investigation system links to suppliers and notifies corresponding internal procurement managers to follow up on investigation progress more efficiently. Suppliers use the latest version of the CMRT published on the RMI website to disclose information on the supply chain of gold (Au), tantalum (Ta), tungsten (W), and tin (Sn) minerals. The group's responsible departments verify and confirm the information disclosed by suppliers based on the company's responsible mineral policy and customer requirements. When risks are identified, they continue to communicate with the suppliers to control and remove the relevant risks, in order to comply with the company's responsible mineral procurement policy and customer requirements. The investigation results are then saved in the CAMP system for at least 5 years.

- In addition to CMRT, our company also uses the CAMP system to send due diligence investigation system links to suppliers for EMRT investigations. At the same time, we notify the corresponding internal procurement responsible person to follow up on the investigation's progress more efficiently. We require suppliers to disclose information on cobalt (Co) and mica minerals using the latest version of the EMRT published on the RMI website. We also save the investigation results in the CAMP system for at least 5 years.

- The CSR department conducts regular checks on the RMI and LBMA official websites to confirm compliant smelters and updates the latest results to the responsible mineral procurement management system for effective management of compliant smelters. Additionally, every quarter, they use the CAMP system to investigate and notify suppliers who are non-compliant or have not responded to CMRT requests.

- Supplier Report Summary Tracking Stage

The responsible department reports the actual investigation status according to the customer's request. This year, our company not only completed the due diligence investigation task, but also further upgraded and optimized the responsible mineral procurement management system, including upgrading the supplier cobalt metal (CRT) management module to the Extended Mineral Report (EMRT) management module, adding quarterly updates notifications for CMRT and EMRT, CMRT non-compliant/qualified notification function, supplier-provided CMRT effective date overdue and not updated vendor code lock reminder function, to provide effective information for suppliers in a better and continuous manner, maintain smooth communication with them, and provide timely support and guidance to suppliers, with the expectation of achieving a more comprehensive and improved risk control effect.

Supplier report analysis and processing

- The responsible mineral procurement management system can analyze the due diligence reports submitted by suppliers and generate summary reports, including the overall response status of suppliers and the due diligence information disclosed by suppliers. The company's responsible units analyze potential problems based on the reports and promote improvement. Subsequently, according to customer requirements, combined summary reports are provided for CMRT and EMRT due diligence reports.

- Quanta will continue to improve the responsible mineral procurement management system, promote social, environmental, and human rights issues, and fulfill its responsibility as a member of the supply chain!

Quanta's 2022 Responsible Mineral Procurement Annual Results